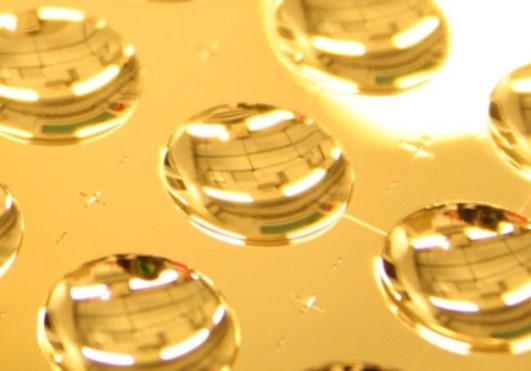

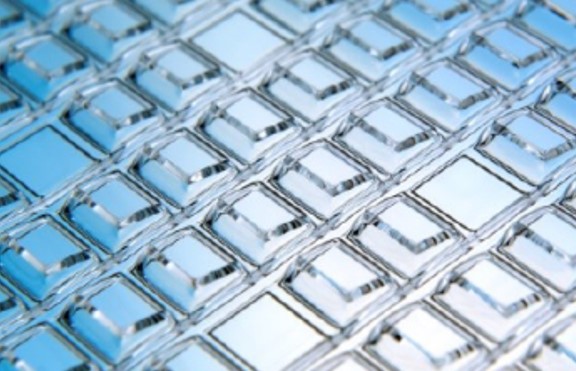

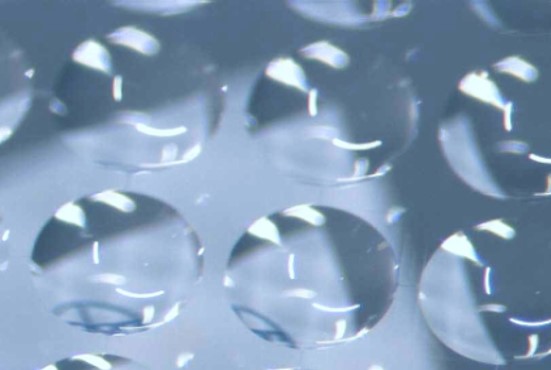

With the help of this unique technology, new components can be manufactured from glass at wafer level for the first time that meet the qualitative requirements of optics. Thus, microlenses, reflectors and specially shaped optical windows can be realized in large quantities at wafer level without further mechanical processing, which enables cost-effective mass production of micro-optical devices (wafers with gold-plated concave mirrors). In combination with MEMS scanners and active optical devices, this manufacturing process is the key to hermetically encapsulated MEMS devices that meet the high demands of optical functionality (MEMS mirrors with slanted windows). The slanted windows avoid the back reflection of the incoming laser beam into the projected image area. The components are integrated into systems and find application in the fields of image projection, light structuring, data transmission by laser radiation and material processing, among others.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology