Accumulator development

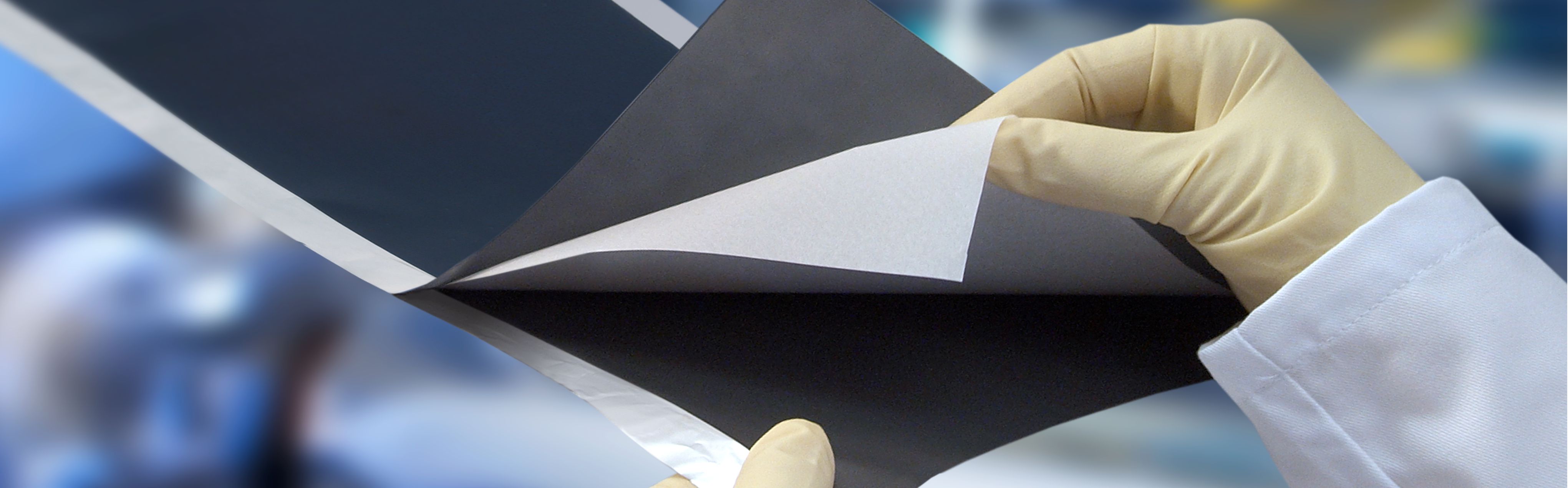

One of the main working fields of the FAB-SH is the further development of existing accumulator systems as well as research and adaptation of novel concepts. The main focus is on new materials, new material formulations for electrodes, novel electrolyte systems and separators. Other work include advanced manufacturing processes leading to an improvement of cell performance, lowering of costs and/or reduction of detrimental effects on the environment. Beyond that, activities are also guided by the need to customize lithium cells for different fields of application. In particular, this refers to optimization of parameters as energy density, power density, cycle stability, long life-time, intrinsic safety as well as the adaption for special conditions of operation. The “pouch-cells” of ISIT enable flexibility of

design in terms of size and shape to match exactly the space requirements for the cells and cell modules.

Cell manufacturing

Based on lithium polymer technology, Fraunhofer ISIT provides a flexible manufacturing platform enabling technical realisation of accumulator development. The production of cells can be divided in two main steps:

- Manufacturing of electrodes and separators

- Assembling of cells

In this context the proprietary separator concept developed by Fraunhofer ISIT is an integral part of the cell technology.

It is exactly matched to the assembling process (lamination) for the production of cells.

By variation of materials in the lithium accumulator its performance can be controlled within a wide range.

In addition, the pouch casing enables an adaption of the celldesign in a wide format range to predetermined dimensions.

By continuous introduction of new materials a considerable „electrochemical system module“ could be generated over the last years. It is adjusted continuously to increasing requirements.

Testing of accumulators

The metrological facilities of IES department offer possibilities for an extensive electrochemical and physical characterization of materials and cells. Material data like specific capacity, impedance, power density, lithiation- and delithiation potentials as well as any occurrence of outgassing rate can be examined in half-cells with 2- or 3-electrode arrangement against lithium.

Further important parameters like cycle stability, impedance and long term stability for a comprehensive understanding of the electrochemical processes can be determined for half- and full cells in a wide temperature range (-40 to + 180 C). On this, numerous test circuits with maximum currents from 100 mA to 100 A are available.

Coating plant and low volume production

Fraunhofer ISIT department IES provides a technology center where laboratory results can be transferred to industrial scale with all sub-steps of production of electrochemical cells.

Within the process chain for manufacturing lithium-ionbatteries both sub-steps of slurry preparation and coating are particularly critical because slight parameter variations could cause a strong impact on the accumulator quality.

Upscaling and optimizing of results from systematically developed research processes are possible by several mixer units, a coating plant and subsequent assembling facilities.

Manufacturing capacities shared with industrial partners assure a rapid implementation of research results to low-volume production so that this process knowledge is also available for industrial partners.

Development and assembling of energy storage systems (module integration, power electronics, BMS etc.) starting with single cells can be realized in cooperation with other departments of Fraunhofer ISIT and/or industrial partners.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology