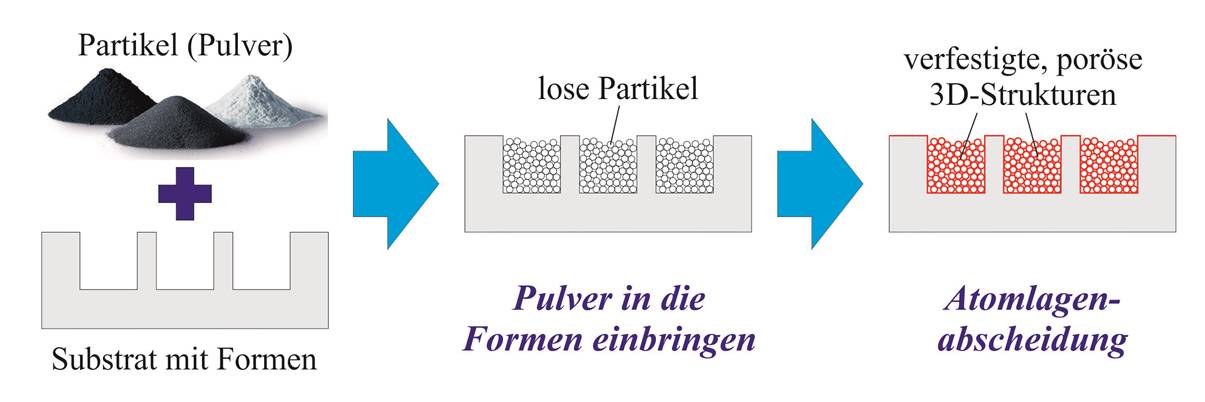

At ISIT, an innovative technological process has been developed that allows the integration of almost any material on planar substrates. It is based on the agglomeration of µm-sized powder (particles) by means of atomic layer deposition (ALD). Similar to the fabrication of ceramic materials, a mold, in this case microcavities in a silicon substrate, is first filled with loose powder. However, instead of sintering the particles under high pressure at 800°C to 1400°C, the substrate with the loose powder is subjected to an ALD process at much lower temperatures.

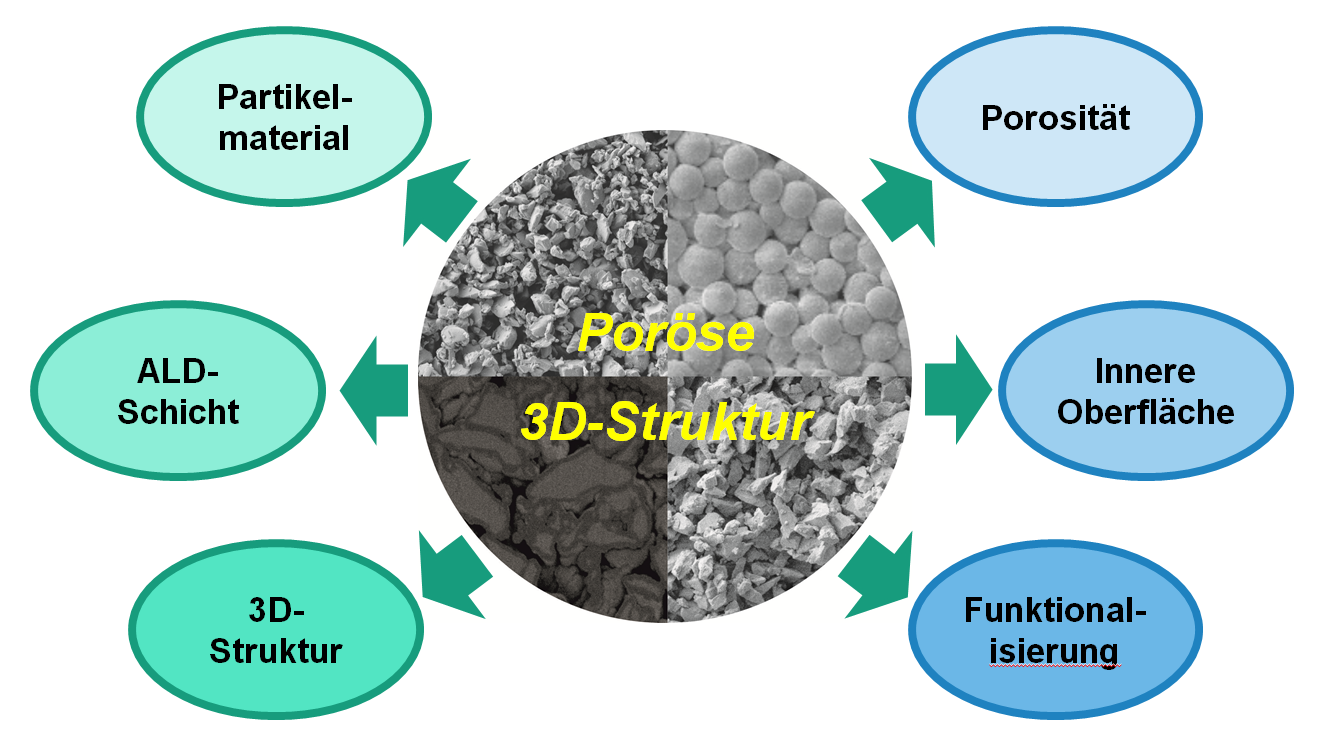

Thanks to the extreme penetration depth of the ALD layer that forms, the particles are bonded together over the entire depth of the microcavities (up to 700 µm) by a layer only 75 nm thick to form firmly connected, porous 3D bodies. These are shrinkage-free, mechanically stable and thermally resistant. Structure dimensions between 50 µm and several mm can be realized with high precision.

Thanks to the almost perfect encapsulation by the ALD layer, the individual particles within a porous 3D body are excellently protected from external influences. Substrates with embedded porous 3D bodies survive standard MEMS and IC manufacturing processes up to 400 °C without damage, so that extensive post-processing in a clean room is possible. The potential applications are extraordinarily diverse. Applications considered so far include integrated permanent magnets made from NdFeB powder. Strong magnetic fields in a very small space are of interest for many MEMS actuators and sensors.

Currently, ISIT is working on vibration harvesters with magnetic force coupling and magnetically actuated scanners. Other promising applications of the new technology include miniaturized, organic-free phosphor converters for solid state lighting (SSL) and a new type of thermal insulation of calorimetric MEMS devices, such as mass flow and gas sensors, that is comparable to conventional vacuum thermal insulation.

Learn about other applications of the new powder-based agglomeration process.

Powder MEMS Technology Platform

Scheme of the procedure

Here you will find a call on the topic:

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology