IGBTs

Tabbed contents

our solution

The most compact electric drive in the world

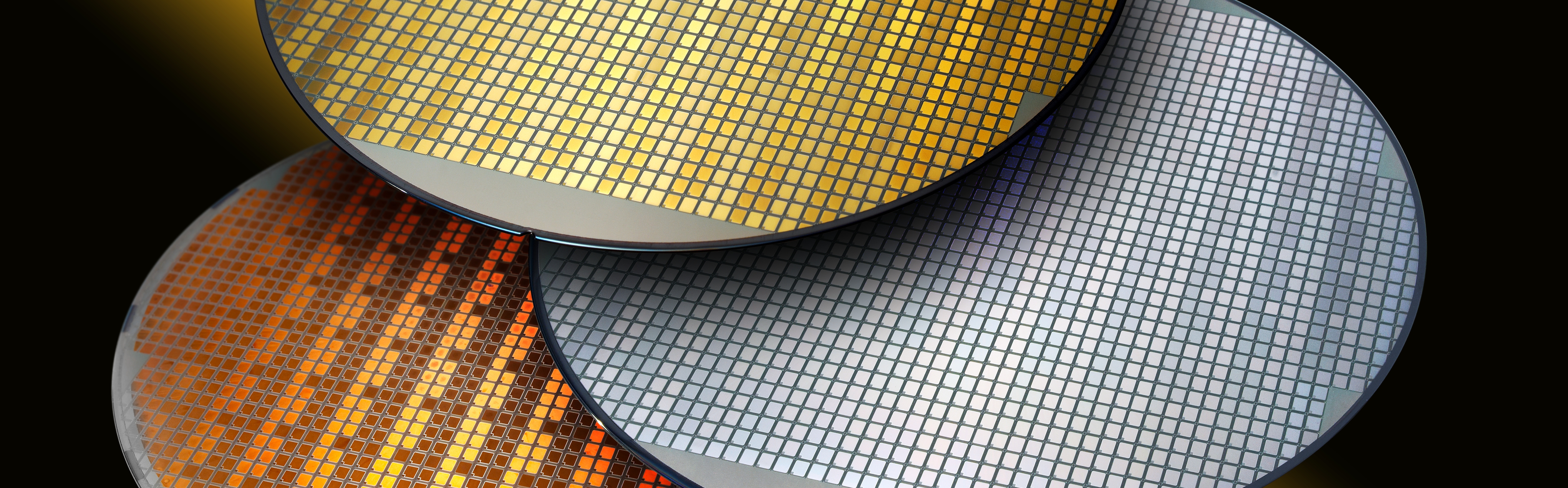

Our approach focuses on developing ultra-thin field-stop IGBTs to increase efficiency. We are also working on adapting advanced assembly techniques that enable better integration into modular electric drive systems, as researched in the ATEM InMOVE flagship project.

Technology

The technologies used in the development of IGBTs and modular electric drives include innovative materials and manufacturing techniques. These technologies aim to increase the power density of electric machines and optimize the efficiency of the entire drive concept.

IGBT: Specifications and technical details

Expand table tab on the right:

Specification of the IGBT

| Parameter | Target value | Layout | |||||

|---|---|---|---|---|---|---|---|

| Temperature | 25°C | 125°C | 150°C | 175°C | |||

| Voltage |

[V] | 1200 | |||||

| Rated currentInom | [A] | 200 | |||||

| Frequency f | [kHz] | 13,5 | Module coarse specification | ||||

| VCEsat (Trade-Off Rg = 1 Ω) dependet | [V] | 1,95 | 2,2 | 2,24 | x | IE-IGBT | |

| Series resistorRG | Ω | 1 | |||||

| Mechanical dimensions: | |||||||

| Chip dimensions | [mm2] | 15,92 x 12,01 | |||||

| Gate-Pad Position | Rim center |

||||||

| Chip-surface (without Gate) (PAD) | [mm2] | 153 | |||||

| Chip thickness | [µm] | 120-140 | |||||

| 1) Power dissipation: from data sheet reference module, internal Rg = 4,7, RGoff = 0,91 Ω, 30 nH, 25°C) | |||||||

| Eon (1200 V, 200 A) | [mJ] | 10,5 1) |

|||||

| Eof (1200 V, 200 A) | [mJ] | 11 1) | |||||

| Etot = Eon + Eoff | [mJ] | 21,5 1) | |||||

| Short circuit time, tsc | with IE: 7,5 µs (150°C, 800V) without IE: max 7 µs (25°, 900 v) | ||||||

| Metallization structure | |||||||

| Front | [µm] | tbd. | Sinterable: Ni-Au or Ni-Pd-Au elektroless | ||||

| Back | [µm] | Ti 50 / Ni 100 / Ag 1000 | |||||

Technical details of the module superstructures

| Technology | STD | IEP5 | IEP5 | IEP4 |

|---|---|---|---|---|

| Module design | Lead-Frame 5 µm Pitch open module |

Lead-Frame 5 µm Pitch open module |

"Mold modules" 5 µm |

"Mold modules" 4 µm |

| 1. Modul series (Mod1) | 2. Modul series (Mod2) |

3. Modul series (Mod3) |

4. Modul series (Mod4) | |

| Superstructure technology, front | Aluminum wire bond on N/Au or Al | Aluminum wire bond on Ni/Au or Al | DBB on Ni/Au Cu Wire bond on DBB | DBB on Ni/Au Cu Wire bond on DBB |

| Superstructure technology, back | Ti/Ni/Ag +Sintering on DCB | Ti/Ni/Ag +Sintering on DCB | Ti/Ni/ag + Sintering on DCB | Ti/Ni/Ag + Sintering on DCB |

| IGBT | STD 1. Generation | IEPS 2. Generation | IEPS 3. Generation |

IEP4 5. Generation |

| Rg, IGBT_intern | 0,7 Ω | 0,7 Ω | 0,7 Ω | 0,7 Ω |

| Metal: Emitter |

Ni/Au | Ni/Au | Ni/Au | Ni/Au |

| Metal: Collector | Ti/Ni/Ag |

Ti/Ni/Ag | Ti/Ni/Ag | Ti/Ni/Ag |

| Diode: Metal: Anode | SMIKORN, SKCD_81_C_120_I4F | |||

| Al | Al | Ni/Au | Ni/Au | |

| Metal: Cathode | solderable, Ni/Ag | solderable, Ni/Ag | solderable, Ni/Ag | solderable, Ni/Ag |

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology