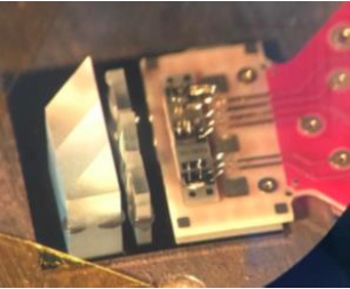

Miniaturized pulsed laser light source

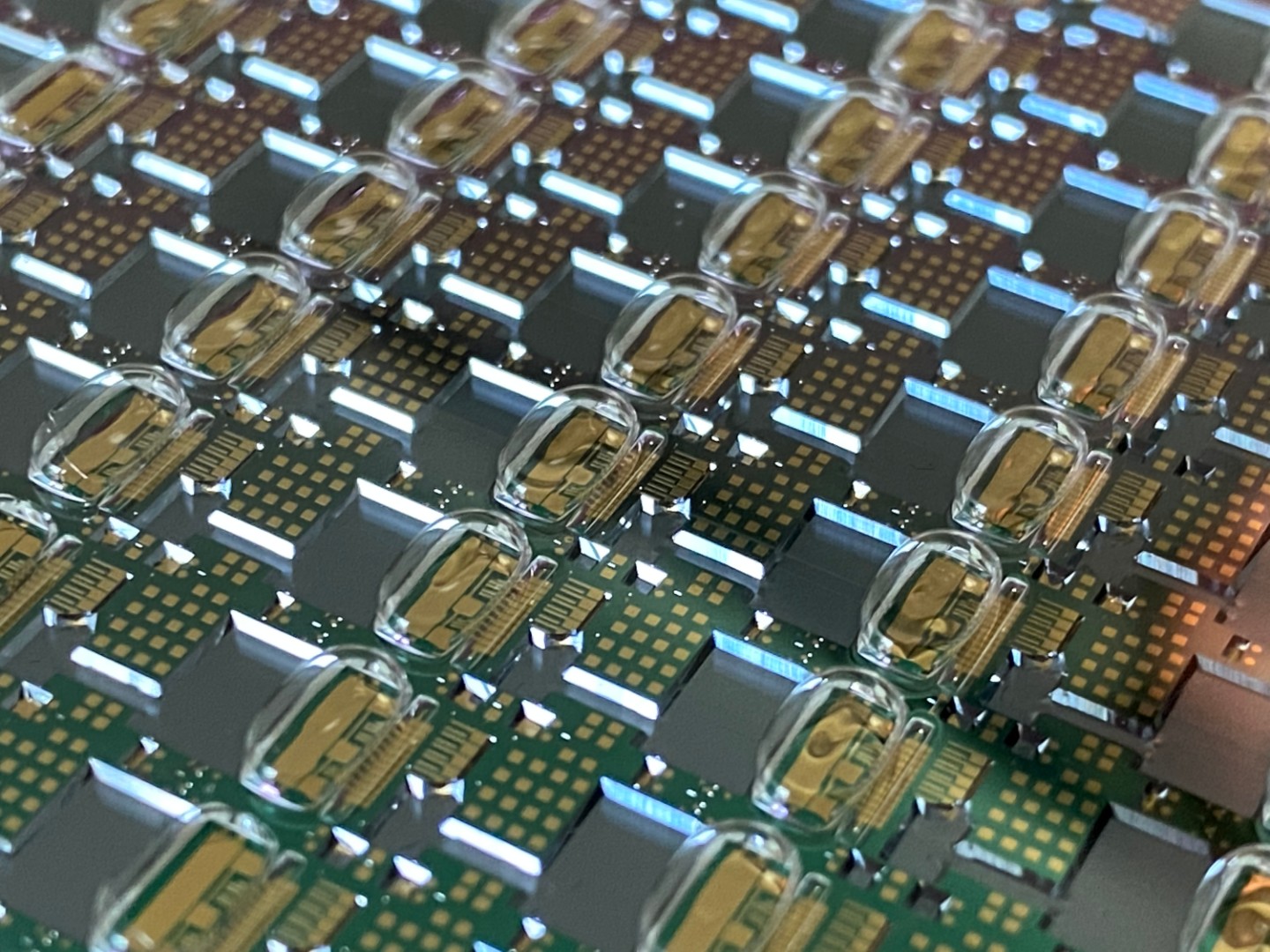

Based on our MEMS wafer processes, we have developed a modular glass/silicon packaging platform for heterogeneous integration of optical components. The glass cover provides a hermetic viewing window. Assembly and wire bonding can be performed on single substrates, panels and 200-mm wafers. Silicon provides the stability required of an optical bench.

Benefits

- Ability to heterogeneously integrate optical components through a modular glass-silicon packaging platform

- Hermetic side viewing window through glass cover

- Required stability of an optical bench through silicon substrate

- Possibility of mounting and wire bonding on single substrates and panels as well as on wafers up to 200 mm in size

In addition to wafer technologies, ISIT offers a whole range of module-level services. These range from special chip-level processes to the production of modules in an industrial manufacturing environment and the investigation of their reliability under accelerated aging.

Thanks to state-of-the-art analysis methods such as high-resolution computed tomography, ISIT is known for its fast and reliable failure analysis of industrial production problems and field returns.

Application areas

- Excitation of multiple atoms

- Manipulation or diverse laser cooling, for example in ion traps or superconducting units.

Technology for: Fourier spectroscopy; compensation of external motions in the optical or atomic beam paths in gravimeters based on atom interferometry; precise adjustment of laser motion.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology