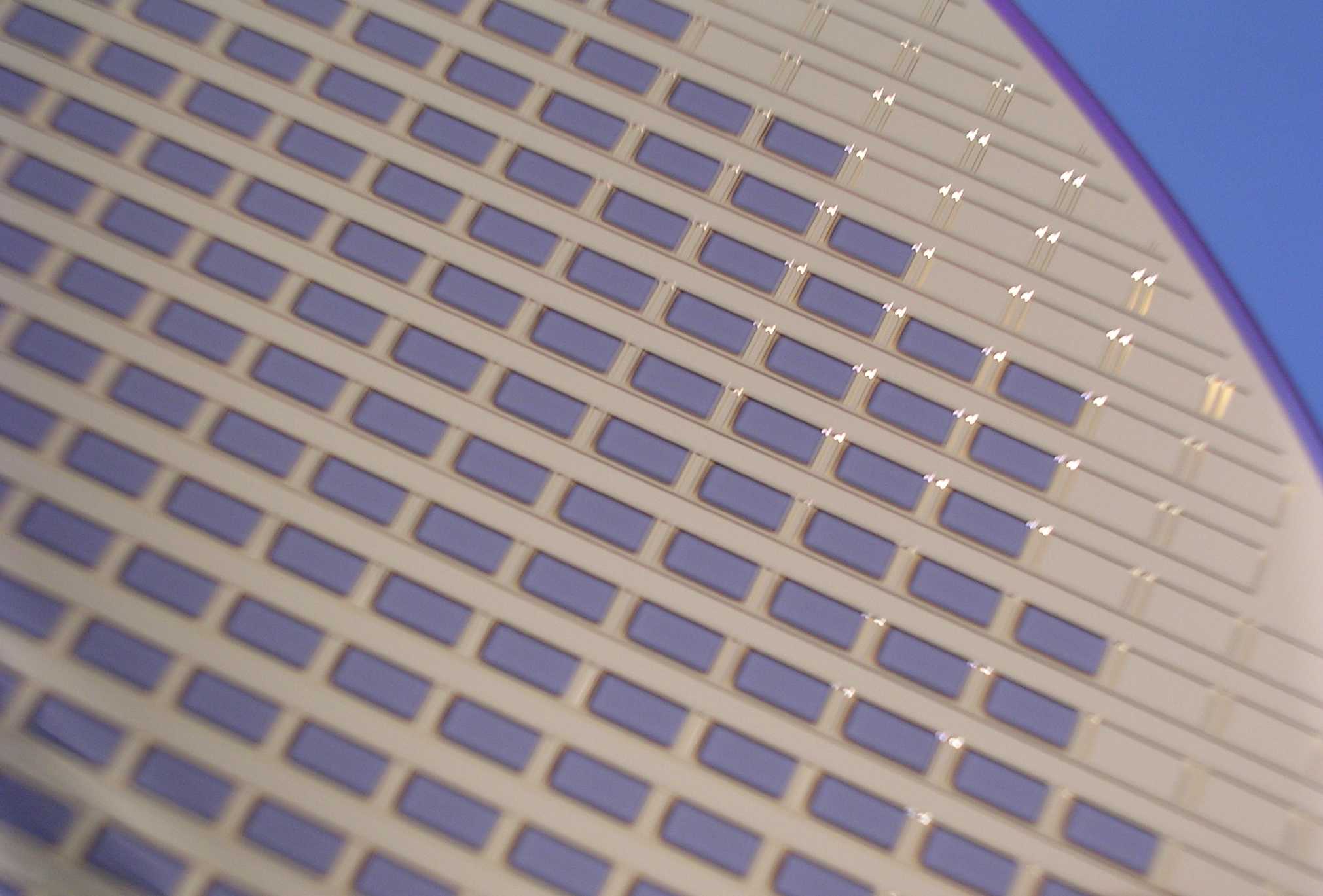

Development and production of functionalized cap wafers is one of ISITs core competences. Depending on the application either glass or silicon wafers are used as base material. Glass wafers are usually processed with 3D glass micromachining, whereas KOH or reactive ion etching are used to form silicon cavities. Applications requiring a vacuum utilize getter layers as “in situ” pumps, whereas anti-reflective coatings are applied for optical applications.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology