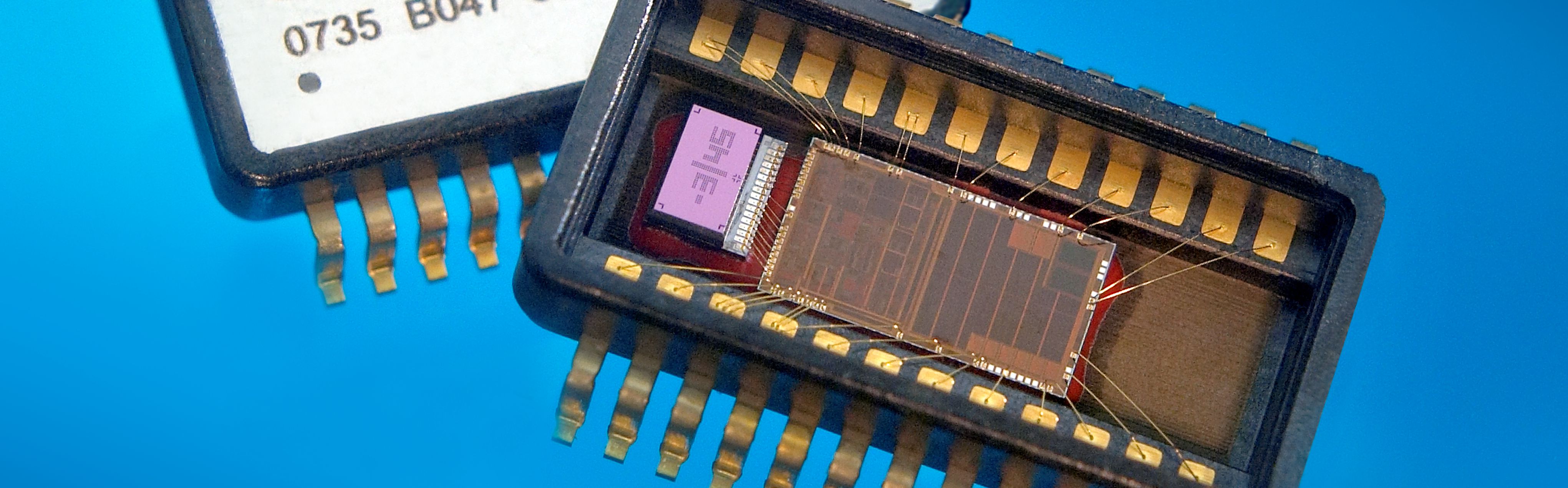

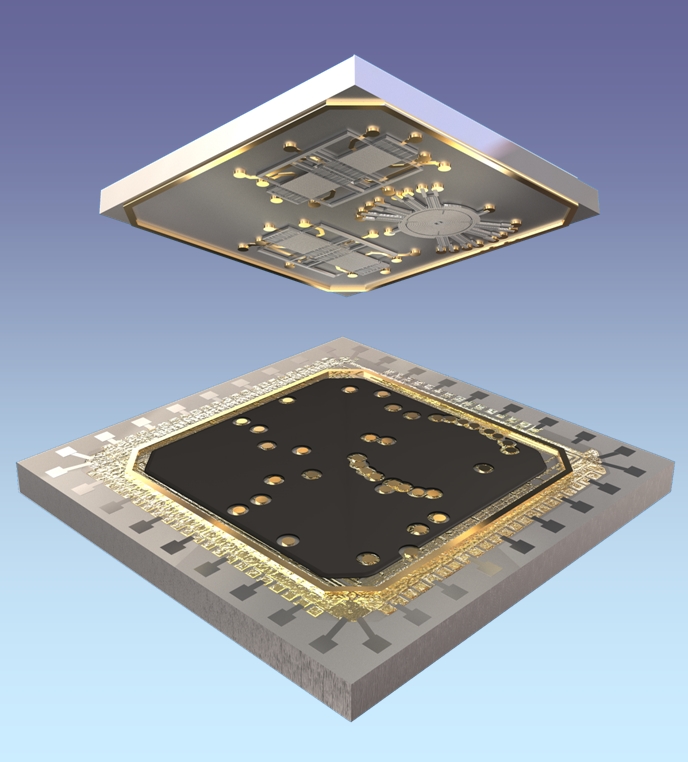

MEMS components often require special assembly techniques, which cannot be realized by standard SMD processing. Besides aspects related to mechanical stress, the combination of MEMS components with other parts like ASICs is a common reason for dedicated housings. The resulting modules are usually referred as “System-in-Package”. Fraunhofer ISIT has a longstanding expertise in system integration of MEMS components, especially in combination with other electronic components like ASICS.

Thanks to a flexible infrastructure and quality assurance ISIT is able to offer the whole process chain from the development of a setup concept up to pilot production of new micro system modules. Following customer requests the packaging development can be accompanied by a FMEA and a control plan. The process can be transferred in a high-volume production environment after successful qualification, e.g. to AEC-Q100.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology