Our offer

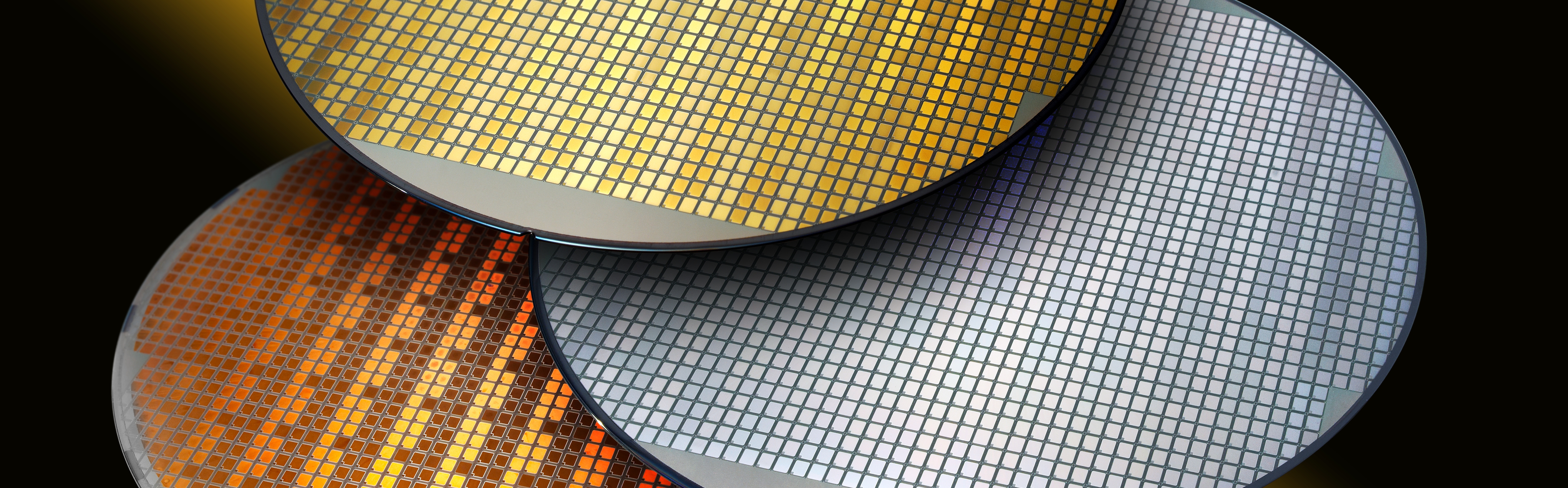

The Fraunhofer ISIT is focusing on vertical GaN power devices, especially on advanced transistor and diode concepts with blocking voltages of some 100 V and switching speeds down to the ns range. The application specific chip designs and processes are facilitated by professional simulation software. The dedicated wafer equipment at ISIT allows the processing of bulk-GaN material with limited wafer diameter as well as 8” GaN-on-Si EPI wafers and the subsequent electrical characterization. As the GaN process line is integrated in a professional MEMS clean room, novel fabrication approaches and unconventional materials can be utilized to explore innovative device and integration concepts.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology