The ongoing trend towards compact wireless audio products (e.g. in-ear headphones) calls for smaller and more powerful loudspeakers, which can no longer be realized with conventional technologies. So-called MEMS loudspeakers, which ISIT has been researching for many years, promise a remedy. Compared to conventional loudspeakers, they are characterized by a smaller size, lower production costs and lower energy consumption, which is particularly advantageous for mobile applications.

In-Ear-Speaker

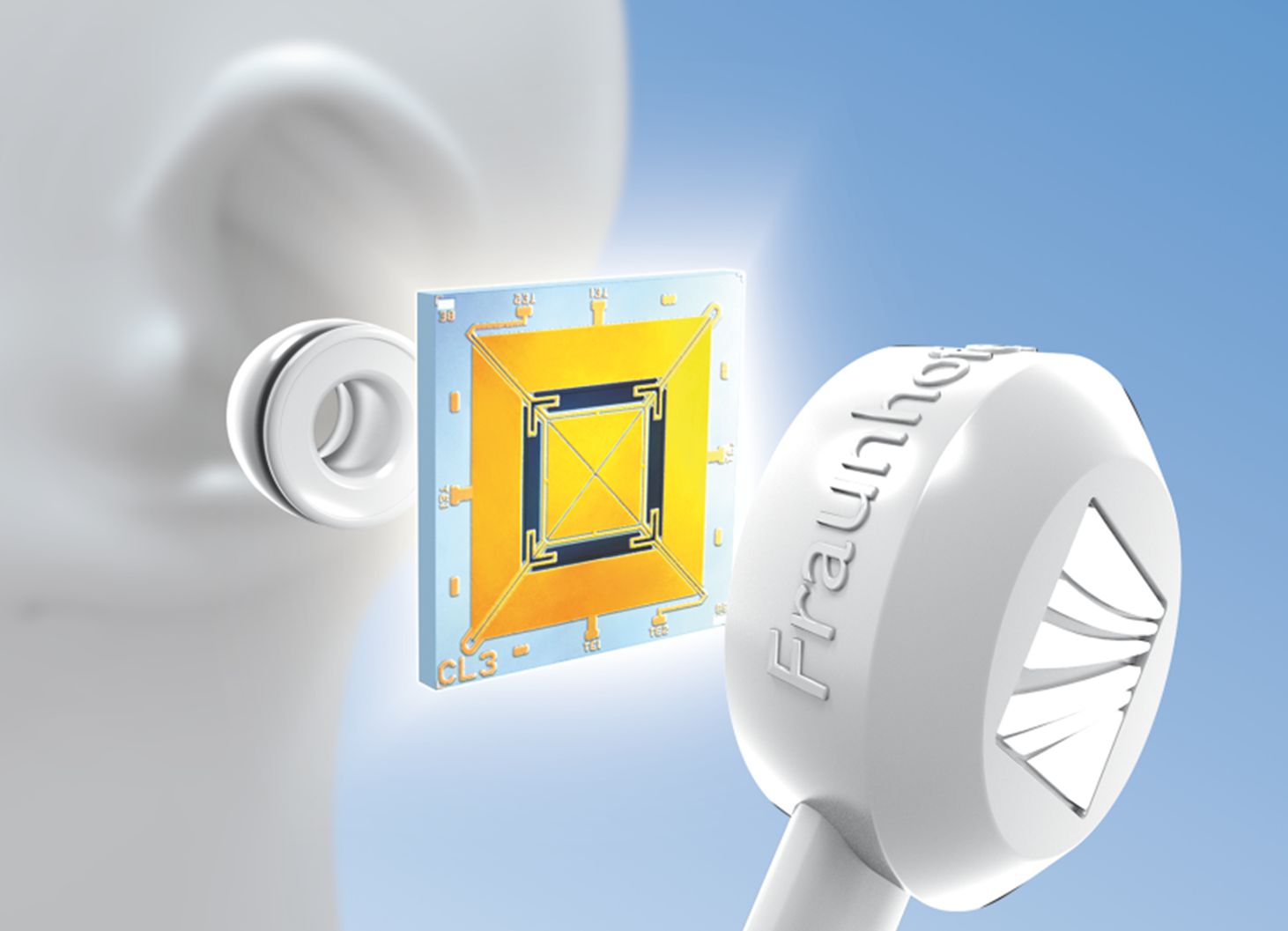

"Due to their properties, MEMS loudspeakers have the potential to become one of the most important advances in the field of miniature loudspeakers," says Dr. Fabian Stoppel, head of the group Acoustic Systems and Microdrives at Fraunhofer ISIT. What is special about these tiny devices is the new MEMS-based drive technology. The abbreviation MEMS stands for micro-electro-mechanical systems. It refers to a special chip technology that can be used to create miniaturized mechanical structures in addition to electronics. The base material for the new loudspeakers is silicon, in which structures with sizes of a few thousandths of a millimeter are created using manufacturing processes from microchip technology.

Functionality:

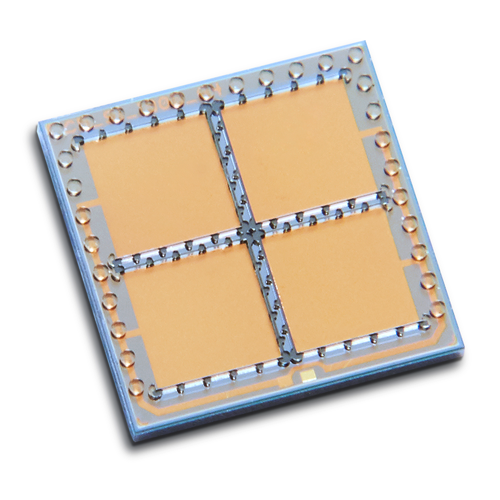

ISIT's novel MEMS loudspeakers work according to the piezoelectric principle. Piezoelectric materials deform under electrical voltage, i.e. they convert electrical energy into motion. If an alternating voltage is applied to the drive structures, which consist, among other things, of a piezoelectric layer two thousandths of a millimeter thick and ultra-thin silicon membranes, they begin to vibrate. These mechanical deflections displace the surrounding air, generating sound waves. The drive principle is very energy-efficient compared to electrodynamic drives and thus enables loudspeakers with a particularly low energy requirement.

The use of piezoelectric materials in technology has been known for a long time. The novelty of MEMS loudspeakers is that during their manufacture, the piezoelectric materials are processed and structured using semiconductor technology processes. As a result, the MEMS loudspeakers can be manufactured in parallel and cost-effectively in large quantities on silicon wafers. Fraunhofer ISIT conducts research in numerous application areas with different piezoelectric thin-film materials and has been an international leader in the field of piezoelectric MEMS for many years.

The MEMS loudspeakers developed at ISIT are now in their third generation - always following the motto "even smaller and even more powerful". In addition to the strong miniaturization, the loudspeakers are characterized by a high fidelity as well as a wide frequency range from 20 Hz to 40 kHz. They are also very energy-efficient and can be manufactured cost-effectively and very precisely in high volumes. These properties make the loudspeakers the ideal choice for applications in mobile devices, e.g. in wireless headphones, hearables, or in the field of medical technology, e.g. in hearing aids.

You might also be interested in

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology