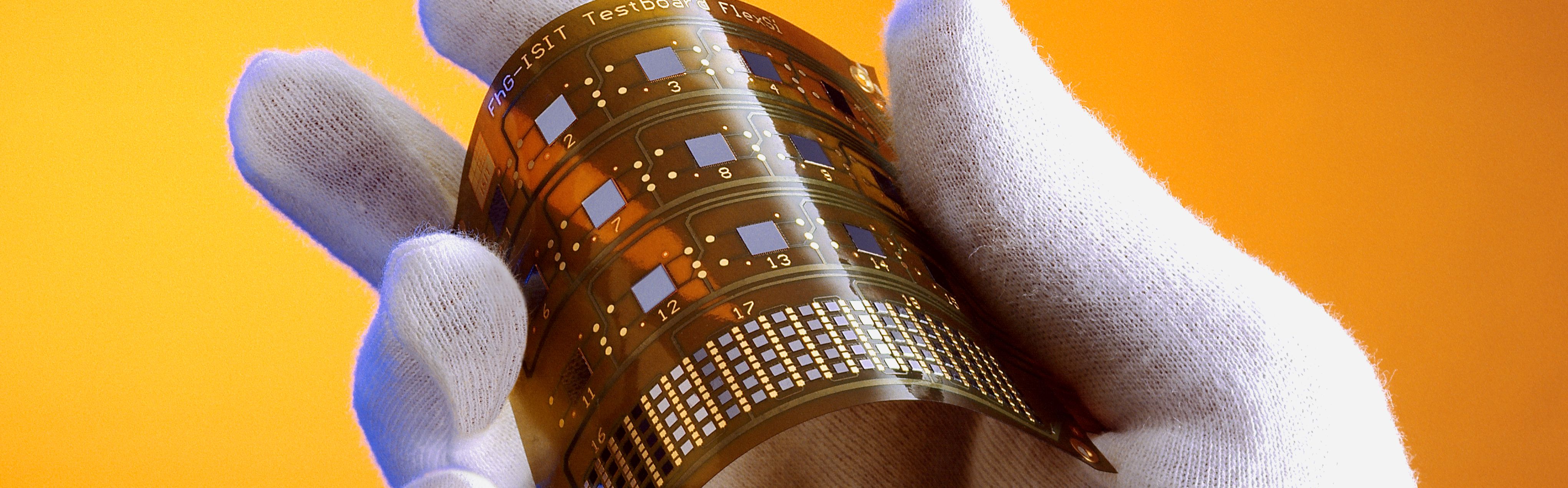

By applying extremely thinned ICs, new electronic components with novel functionality and performance can be realized: The flexibility of thin chips allows their integration in paper, tickets or chip-cards. Chip stacking leads to very small and efficient functional modules. In power electronics, the thickness of a power switch directly affects its electrical and thermal properties.

Fraunhofer ISIT has developed a technology for processing thin silicon chips with professional standard production equipment: wafer-bumping, dicing, and ultra-thin molding using dam & fill. Flip-chip components as well as wire-bonded chip stacks can be produced as functional samples for demonstration purposes or as qualified prototype or pilot production. Transferring the process to line production is facilitated by the very complete infrastructure of ISIT with industrial state-of-the-art equipment.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology