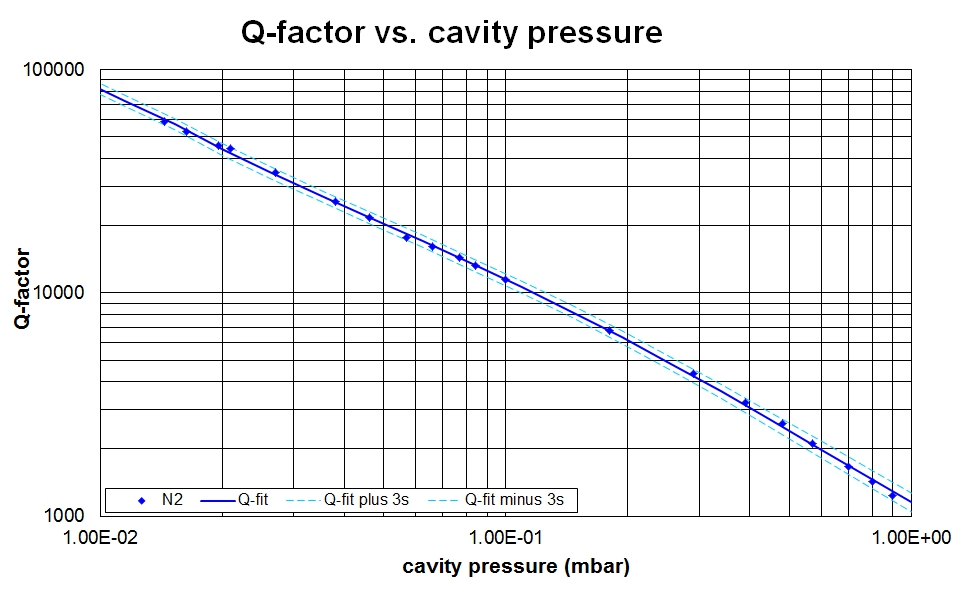

An extremely long lifetime up to 20 years is required by many applications today. To fulfill this requirement the hermeticity of the sealing has to be verified. The air leak rate, which quantifies how much gas penetrates the sealing per time, is the main criterion to calculate the estimated lifetime of the device. If this value is known, the required getter capacity can be calculated easily. In case of very small cavities, as they are formed by wafer-level packaging, air leak rates smaller than 10-14 mbar l/s have to be measured, which is nearly impossible by conventional techniques.

The patented Neon ultra-fine leak test has been proven to detect leak rates as small as 10-17 mbar l/s. The only requirement is a micromechanical resonator with a high Q-factor. During the test a batch of wafers is placed in pressure chamber which is filled with Neon. After some hours, Neon is diffused into the leaky devices. Since the getter does not interact with the Neon, the cavity pressure increases rapidly, resulting in a mechanical damping of the resonator. A following measurement of the Q-factor allows quantitative statements on the gas leakage.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology