Assessment of Quality and Reliability

- Electrical Measurements (e.g. verification of characteristic datasheet specifications)

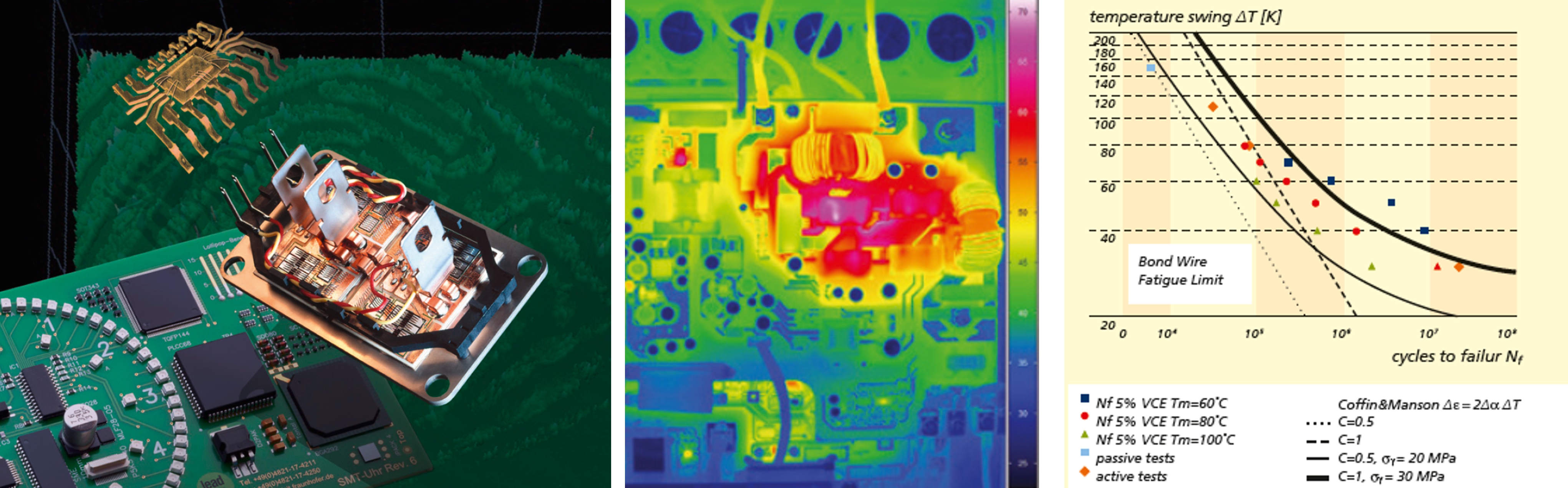

- thermal measurements (e.g. by infrared thermography)

- static thermal resistance (mW...kW)

- heating behavior

- transient heat distribution (thermal impedance)

- power cycle tests up to 2000 A

- temperature cycles

Material related evaluation of electronic assemblies

- analysis of thermo-mechanical behavior

- description of damage mechanisms, failure analysis and damage level evaluation in solder joints and bond contacts by metallurgical methods

Evaluation of Reliability and Lifetime Prediction

- product lifetime prediction based on observed damage mechanisms

- transfer of mission profile under actual operating conditions (active and passive temperature changes) to test cycles

Thermal Engineering

- simulation of the heat balance (components, modules and assemblies)

- modelling of static thermal resistance

- modelling of transient heat distribution (heating behavior)

- modelling of mechanical loads due to material incompatibility (thermo-mechanical mismatch, warpage of layer composites, solder creeping)

- heat sink calculation, e.g. dimensioning of air- and liquid coolers

- evaluation of cooling concept efficiency

Development of Assembly Concepts

- optimisation of thermal resistance

- evaluation of relevant characteristics in production quality and reliability

- prototype manufacturing

- power balling

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology