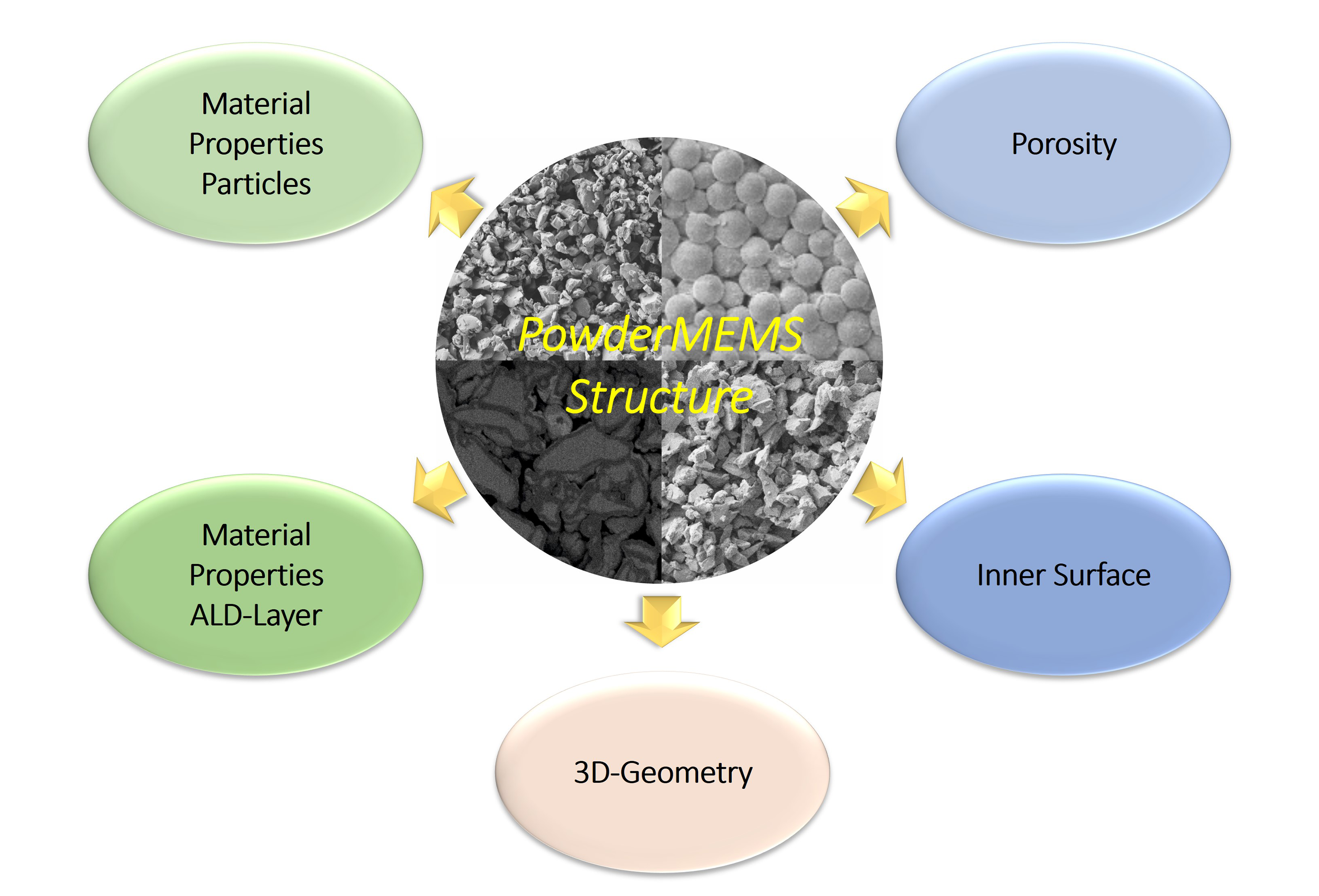

The multiple degrees of freedom of the PowderMEMS process enables the creation of functional microstructures for a wide range of applications.

Functional MEMS structures

Thermal management

Thermal management with PowderMEMS

Our solution approach:

- Fabrication of porous microstructures with variable thermal properties

- Cooling and thermal isolation of MEMS

- Integration into existing designs on 200 mm / 8" Si wafers possible

By using appropriate powders, PowderMEMS can be used to produce porous microstructures with very high or very low thermal conductivity. By using e.g. metal powders, microcoolers with permeable structures can be created directly on wafer-level. Thus, efficient liquid cooling can be integrated on the Si wafer directly underneath a heat source. By using thermally poorly conducting powders, on the other hand, very good thermal insulation and simultaneous mechanical stabilization of thermal MEMS on e.g. thin film membranes can be achieved.

Application examples for thermal management with PowderMEMS:

- Integrated liquid cooling of a micro coil

- Thermal insulation of a thermal flow sensor

Integrated micromagnets

Integrated micromagnets

Our solution:

- Micromagnets integrated on substrate level

- Any hard and soft magnetic materials: NdFeB, SmCo, ferrite, carbonyl iron etc.

PowderMEMS enables the precise integration of micromagnets made of any magnetic material and in any shape on wafer level. This enables a high degree of miniaturization, optimal magnetic field geometries and a significant saving of raw materials.

Possible applications:

Porous structures

Porous microstructures

Our solution:

- Porous microstructures integrated on substrate level

- Almost any selection of dry powders in the µm range

- Very large internal surfaces with small wafer footprint

PowderMEMS enables the precise integration of porous microstructures made of almost any material and in any shape at wafer level. This enables a high degree of miniaturization, and the integration of very large and, if required, reactive internal surfaces.

Possible applications:

- Protective caps for MEMS environmental sensors

- Catalytic surfaces for MEMS sensors

- Immobilization of (bio)molecules in MEMS

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology