Electrical Characterization

Tabbed contents

Our solution

Fraunhofer ISIT provides you with a professional measurement technology platform that covers all common methods of electrical characterization and also integrates state-of-the-art analysis methods:

- Static and dynamic parameter measurements (IV/CV, pulse measurements, Rds(on), switching characteristics)

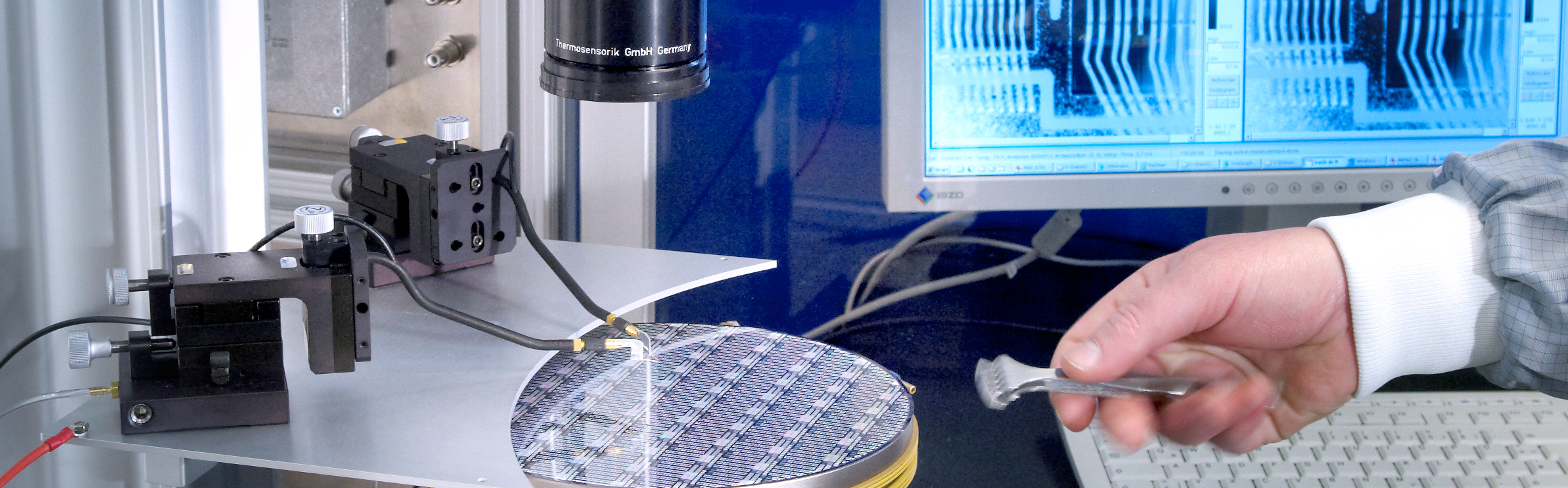

- Fault analysis with lock-in IR microthermography for hot spot detection

- Structural analysis using scanning electron microscopy (SEM) and focused ion beam (FIB)

- Tests at wafer, PCB, and module level – all available 24/7 at the ISIT site

Technology

- Wafer-level tests: IV/CV characteristics, pulse and temperature-dependent measurements

- PCB & modules: Functional tests under real operating conditions, voltage resistance, switching cycles

- Lock-in IR microthermography: Localization of thermal anomalies

- SEM & FIB: Surface analyses, precise cross sections and material characterization

- Virtual cleanroom tour: Online insight into our MEMS production

Applications

- Characterization of PowerMOSFETs and IGBTs directly at wafer level

- Fault analysis for module failures in power electronics

- Parameter tests for analog and mixed-signal ICs

- Qualification of MEMS sensors prior to system integration

Benefits

- Comprehensive service: development, testing, and analysis from a single source

- Highest measurement accuracy and resolution thanks to state-of-the-art measurement technology

- Fast troubleshooting and targeted process optimization

- Permanent availability and virtual cleanroom tours

- Seamless integration of characterization and production at the ISIT site

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology