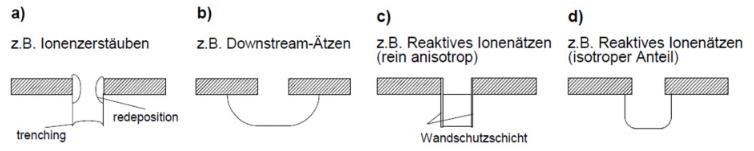

The reactive ion etching is an ion-assisted reactive etching process. Because of the good controllability of the etching behavior (homogeneity, etch rate, etch profile, selectivity), RIE is a method for the production of topographical structures for micro- and nanosystem technology. The process allows both chemical-physical removal of both an isotropic (direction independent) and an anisotropic etching. The etching is performed by charged particles (ions) generated in a gas plasma. A corresponding masking (eg generated by photolithography) of the surface gives the shaping of the structures. In reactive etching, the chemical etching reaction is triggered only by the kinetic energy of the incident ions. From the gas ion and the layer molecule of the surface, the volatile etching product is formed, which is removed by the vacuum system. RIE provides very good results even with very fine structures with dimensions well below 100 nm.

Reactive Ion Etch (RIE)

Characteristics:

Selectivity, etch profile, etch rate, homogeneity, reproducibility - is precisely adjustable in reactive ion etching by the gases used and the process parameters (generator power, pressure, gas flow). Both an isotropic and an anisotropic etch profile are possible.

Application areas:

- Semiconductor technology

- microreactors, micro flow sensors, microswitches, optocouplers, micromotors, biosensors

- Smallest components for movable and immovable microstructures

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology