The awareness for efficient power electronic module integration is increasing dramatically. Smart control of energy-consuming applications and their intelligent system integration offer many benefits:

- miniaturization

- cost reduction

- energy savings and

- increased reliability

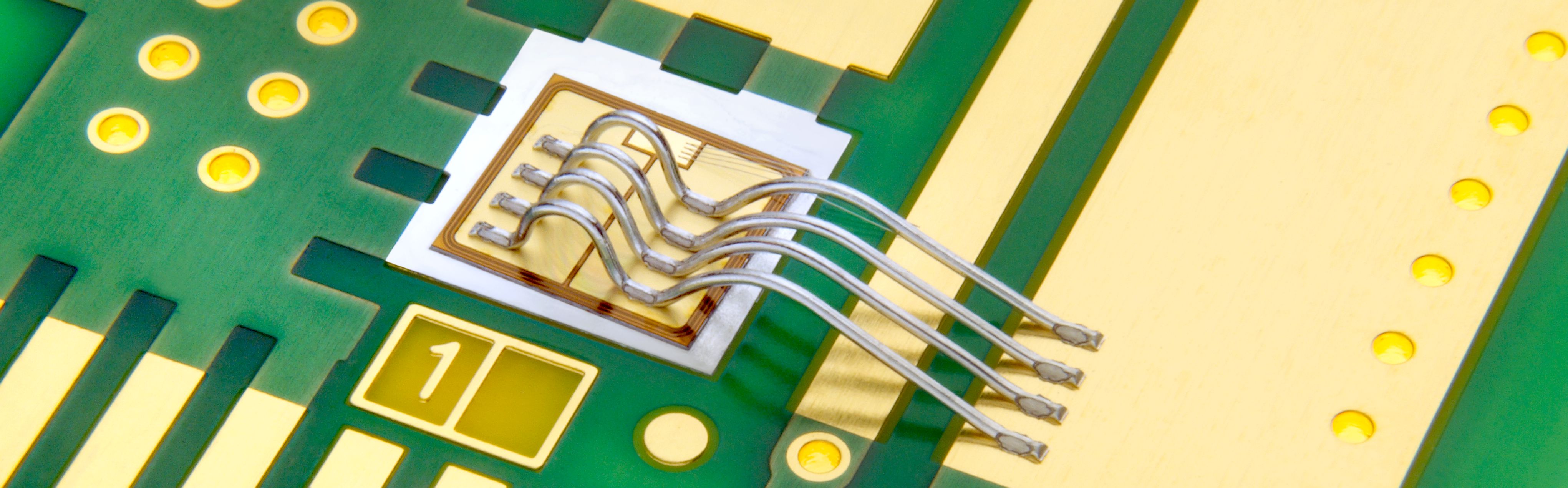

Among the development of new assembly technologies, the ISIT equally offers the production of customized assemblies and prototype series. Special experience lies in the assessment of quality and reliability, e.g. by a thermal analysis of assemblies and electrical load cycling tests. The services offered at ISIT comprise substrate design, assembly and interconnect technologies and full module qualification. For mounting semiconductor power components, die soldering under vacuum or inert gas atmosphere can be performed as well as Ag sintering.

Equipment

- Wafer dicing saws

- Die bonder, inline and batch die soldering

- Thin wire bonder (ball- and wedge bonder)

- Thick wire bonder

- Dispenser for encapsulation

- Electrical load testing up to 600 A

- Quality and reliability assessment techniques

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology