Humans and robots are already close colleagues in many workspaces. This opens up the possibility of optimally complementing the cognitive and flexible capabilities of humans with the precision and endurance of robots and achieving maximum productivity. However, a prerequisite of this human-robot collaboration (HRC) is a high degree of reliability and integrability. Previous sensor solutions cannot realize comprehensive intelligent coverage of the environment. Micromechanical ultrasonic transducers (MUT) represent an innovative and effective further development that opens up new areas of application thanks to their compact design and power efficiency.

Ultrasonic sensors

Ultrasonic sensors are already used today in numerous application areas for environmental monitoring and object detection: Parking assistance in automotive technology, presence detection and level measurement in factory automation, and navigation of mobile robots are just a few examples. Distances in the range of a few millimeters to a few meters are covered. The basic measurement principle behind this is that a transducer emits an ultrasonic wave and then detects the echo signal. Quantitative statements about distances and movements of obstacles within the sensor range are derived from the transit time and a frequency shift of the reflected signal.

Compared to optical methods, ultrasonic methods are characterized by the fact that distance and motion detection can also be used in dark or opaque environments and requires less detection effort due to longer signal propagation times. In addition, ultrasonic methods can be designed in a very energy-efficient manner due to their principle and can be miniaturized to a relatively high degree.

At present, ultrasonic sensor systems are mainly realized using leaded piezo-ceramics and composite compounds by means of precision mechanical manufacturing processes. However, the increasing complexity of measurement and testing tasks in MRK requires an increasing degree of sensor miniaturization, for example for embedding in reactive gripper systems. Furthermore, conventional approaches are limited in terms of resolution capability as well as RoHS compliance and thus will not meet the requirements of the next generation of robots.

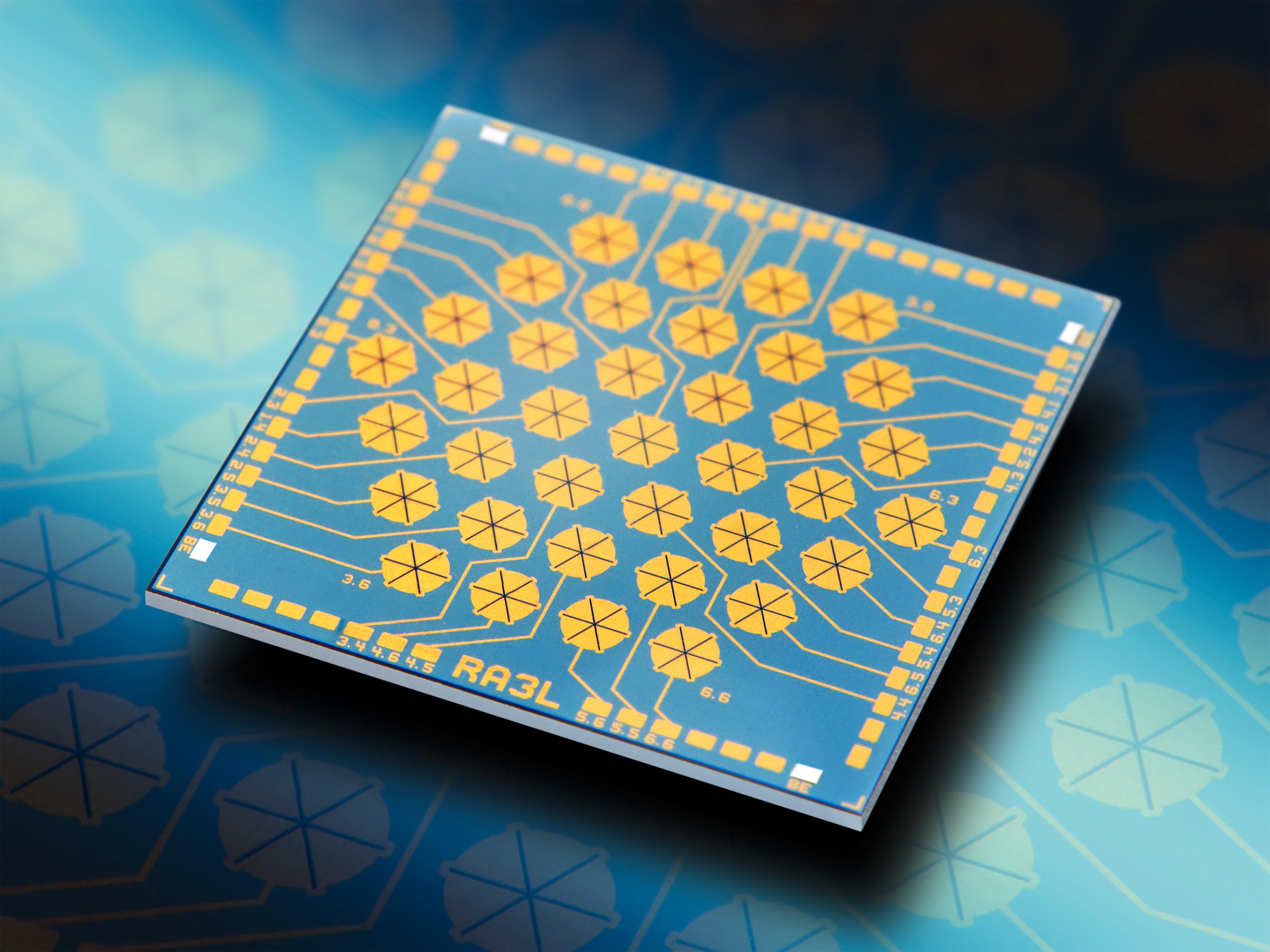

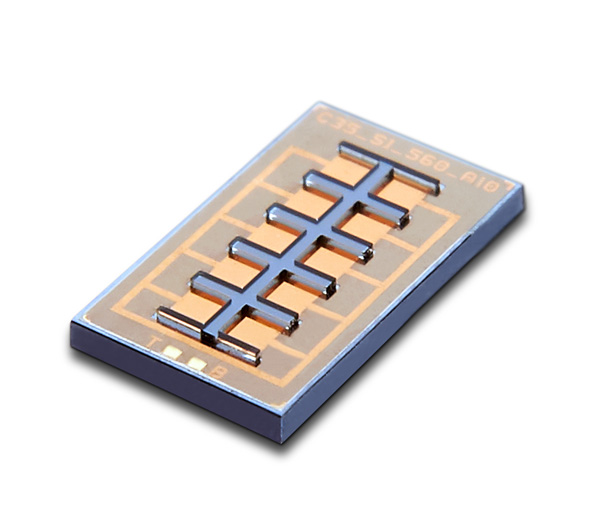

Ultrasonic transducers based on microelectromechanical systems (MEMS) have the potential to overcome these hurdles. These micromechanical ultrasonic transducers (MUTs) benefit from reliable semiconductor technology manufacturing processes that enable low-cost, high-volume production of sensors. MUTs are manufacturable for a wide range of ultrasonic frequencies, enabling application-specific ranges and resolving power. Sensor solutions can be manufactured in single-channel structures as well as in arbitrary two-dimensional array structures. In the latter, different ultrasonic transducers are arranged close to each other, which opens up a whole range of new application possibilities. For example, the position of objects can be reliably mapped in three-dimensional space by correlating the signals received with different transit times with the position of each transducer (beam forming). On the other hand, it is possible to direct the transmission of an ultrasonic wave so that it hits exactly one targeted point in space (Beam Steering). MUT arrays of this type generate focused, high-intensity sound beams that facilitate the detection of the environment. This enables three-dimensional environmental monitoring based on imaging techniques.

In combination with on-chip sensor control and embedded AI, intelligent MUT systems could be available in the future for integration into sensor networks for multimodal environment monitoring, making collaborative interaction between autonomous robot systems and humans even more efficient.

You might also be interested in

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology