Micromechanical and micro optical components (MEMS/MOEMS) made from silicon are sensitive to mechanical stress. Temperature drift or the non-achievement of the target specifications after assembly are possible consequences. The causes for mechanical stress are manifold. The volumetric shrinkage of polymers during curing or different expansion coefficients of the used materials are typical sources of problems.

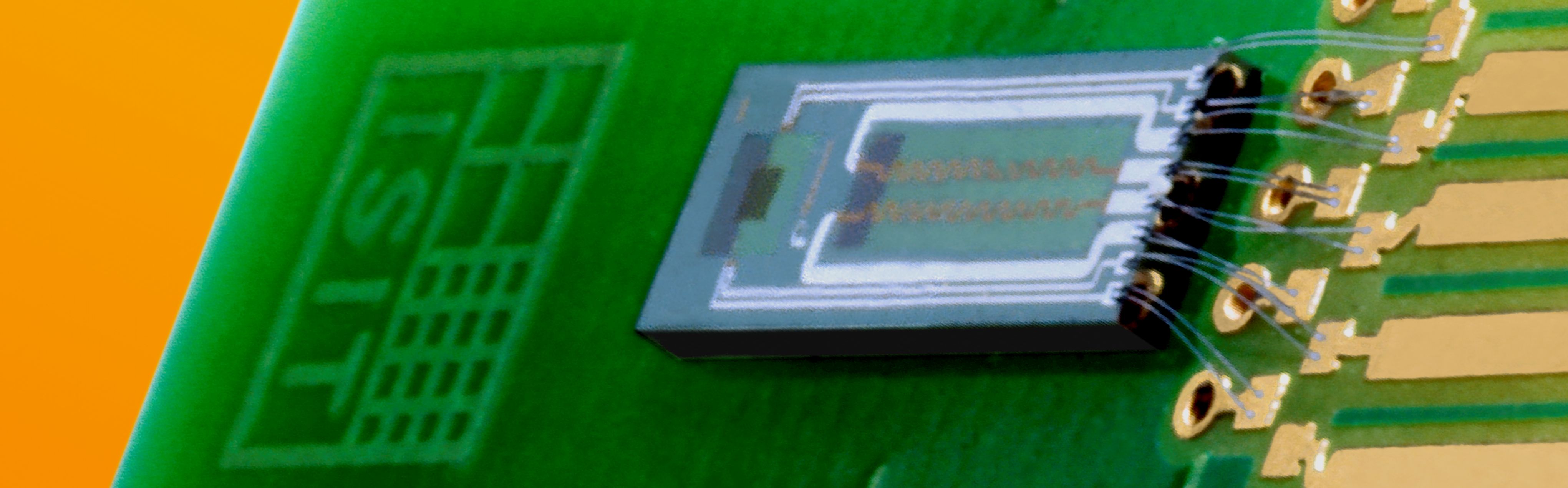

Based on that knowledge, ISIT develops stress optimized mounting and housing techniques for silicon sensors or actuators involving fundamental work on analytical assessment of stress or finite-elements-modelling (FEM).

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology