MEMS Applications

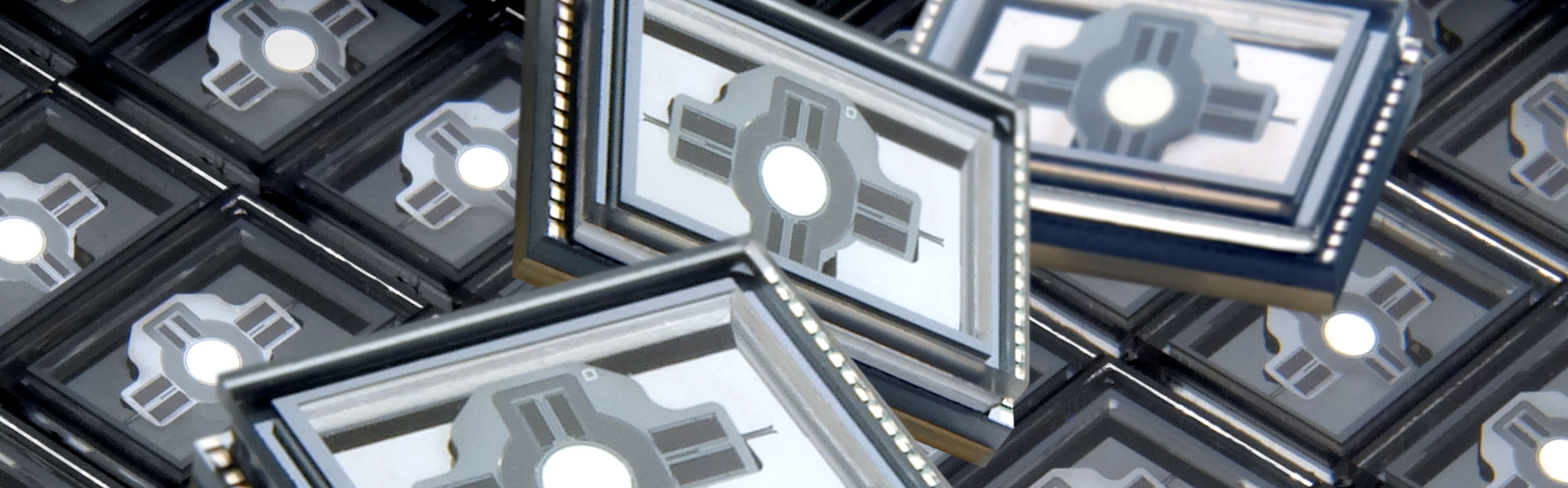

Optical Systems

A major focus in this business area is optical microsystems. Fraunhofer ISIT develops vector scanners as well as resonant MEMS scanners including drive and readout electronics for different types of laser projection displays, for optical measurement and detection systems (e.g. LIDAR), for applications with high laser power in the field of material processing and generative manufacturing as well as for use in optical telecommunication.

Acoustic Systems and Micro Actuators

Another focus in this business area is acoustic microsystems. In this fast-growing field, Fraunhofer ISIT is an international leader in research on novel, highly miniaturized loudspeakers for applications in wearables, hearing aids, AR/VR, wireless headphones and smartphones.

Ultrasound-based microsystems, e.g. for 3D distance measurements, as well as haptic human-machine interfaces form another research area.

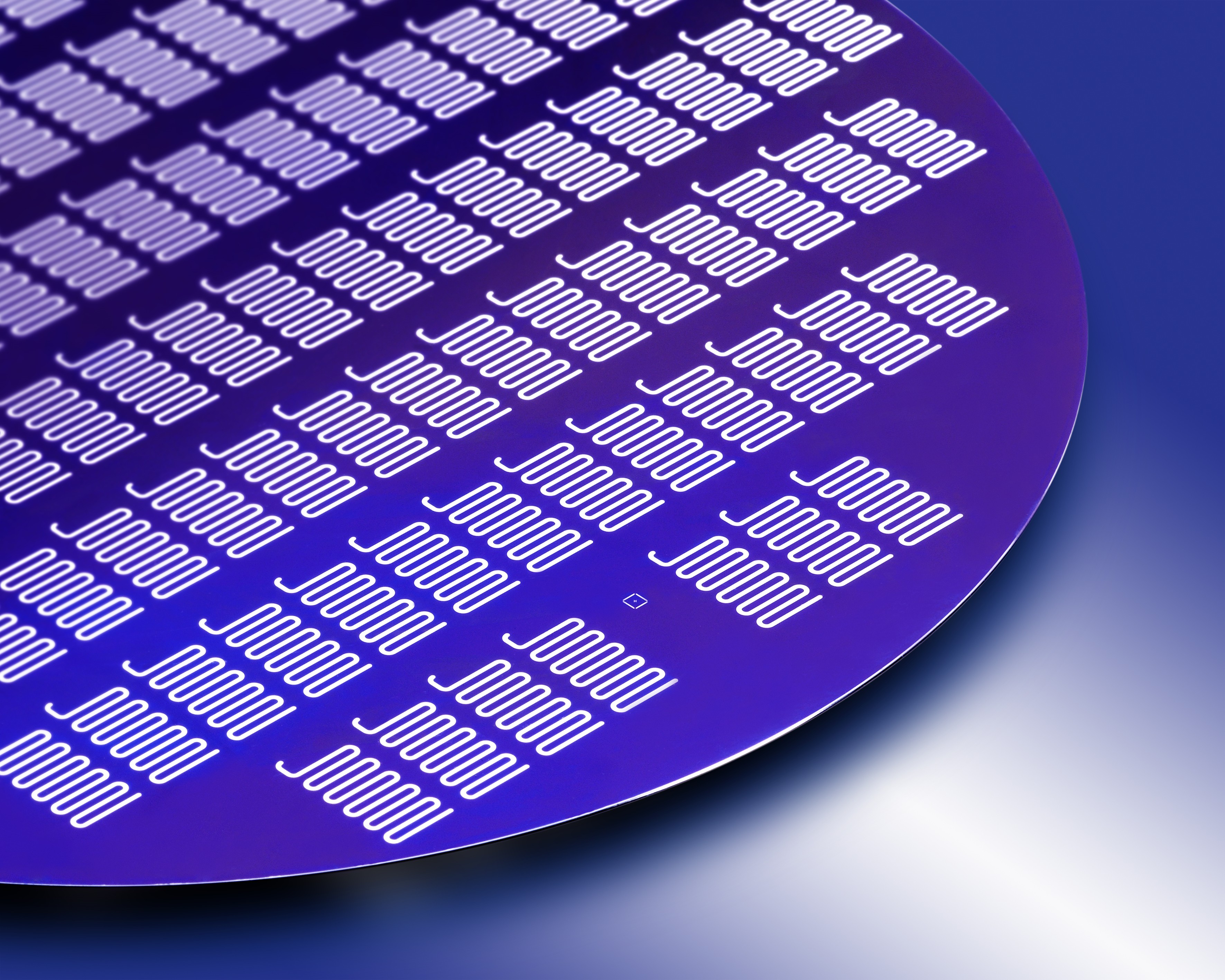

PowderMEMS

A new focus in the business area is agglomerated microsystems. Based on a manufacturing technology developed and patented at Fraunhofer ISIT, the group develops innovative microcomponents for applications in the fields of MEMS sensors and actuators, microfluidics, energy harvesting, and microelectronics.

In addition to agglomeration technology, ISIT has extensive expertise and equipment for the realization of complete components. Pre- and post-processing by means of numerous clean room processes allow the optimal integration of agglomerated components for the improvement of existing or the realization of newly developed microsystems.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology