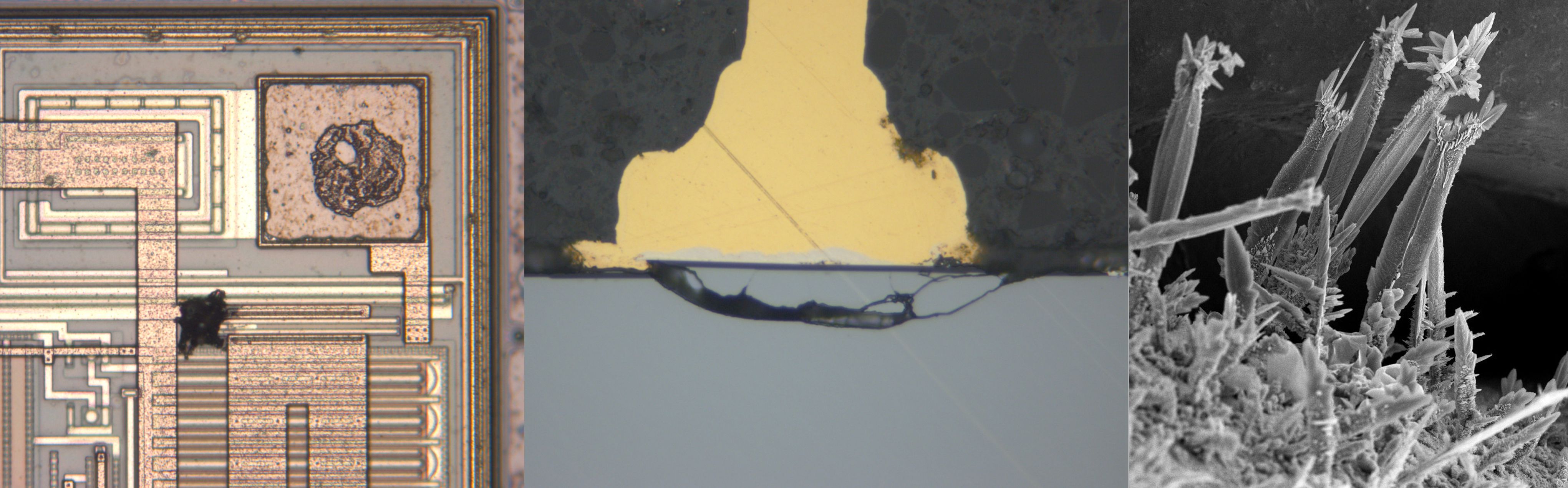

Material- and Damage Analysis

Evaluation of production materials (solder, solder paste, flux, adhesives), electronic components, printed circuit boards and assembled modules by

- wetting force measurement

- mechanical testings

- determination of layer thickness

- cross-section preparation

- scanning electron microscopy and EDX analysis

- microfocus X-Ray imaging

- computer tomography

- acoustic scanning microscopy

- infrared spectroscopy (FTIR analysis)

- etching of solder joints and copper metallization

- decapsulation of molded packages

- detection of lead

Contamination, Corrosion and Residual Substance Analysis

- identification and localization of residual substances

- surface resistance measurements

- evaluation of coatings (thickness homogeneity, curing)

Assessment of Manufacturing Quality according to Industry Standards

Solder joint assessment according to IPC-A610:

- solder meniscus formation

- solder fill in Through-Hole Technology

- de-wetting

- detection of solder joint properties like contact angle, metallurgical structure, grain boundary layers (phase formation), short circuits due to solder bridges and -beads, open contacts, missing solder, infringement of isolation clearance, incomplete liquefaction

- component positioning (lateral displacement, rotation error, polarity, overhang)

- tombstoning

- component damage by thermal overload (popcorning, pad lifting)

Electrical Measurement

- verification of specification datasheet

- high frequency parameter analysis up to 40 GHz

- measurement in climate chamber

Reliability Assessment

Degradation by thermal and/or mechanical loads:

- cracks in solder material by aging

- substrate damage

- dissolution effects on printed circuit boards and components

- documentation of solder alloy microstructures and interfaces

- identification of inter-metallic phases

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology