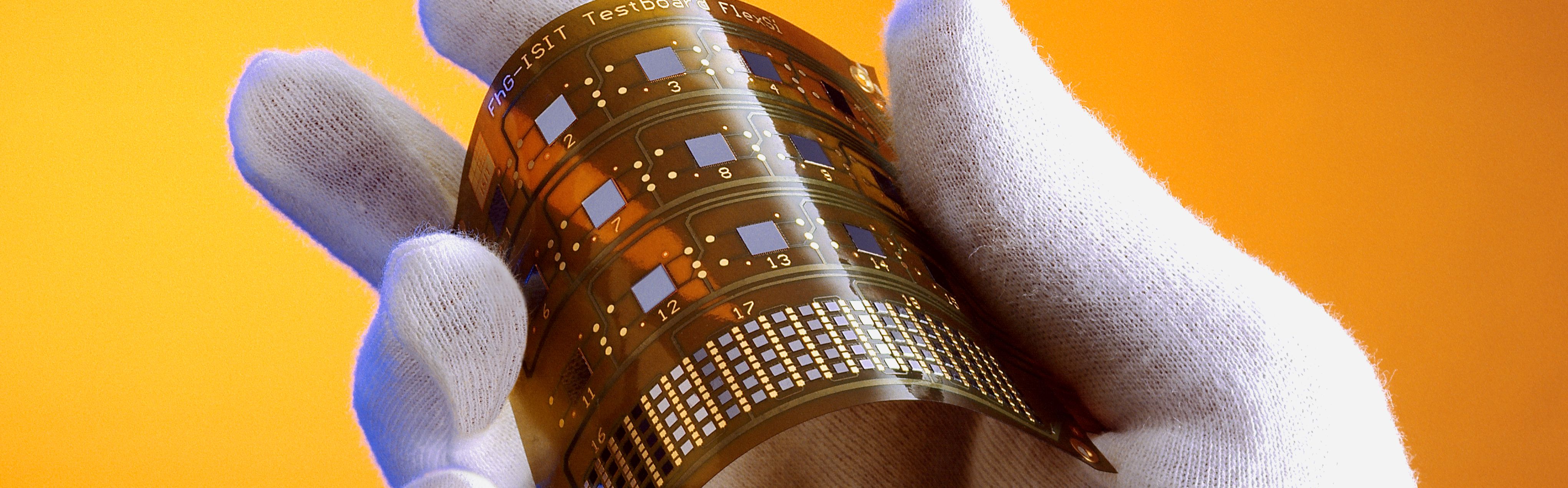

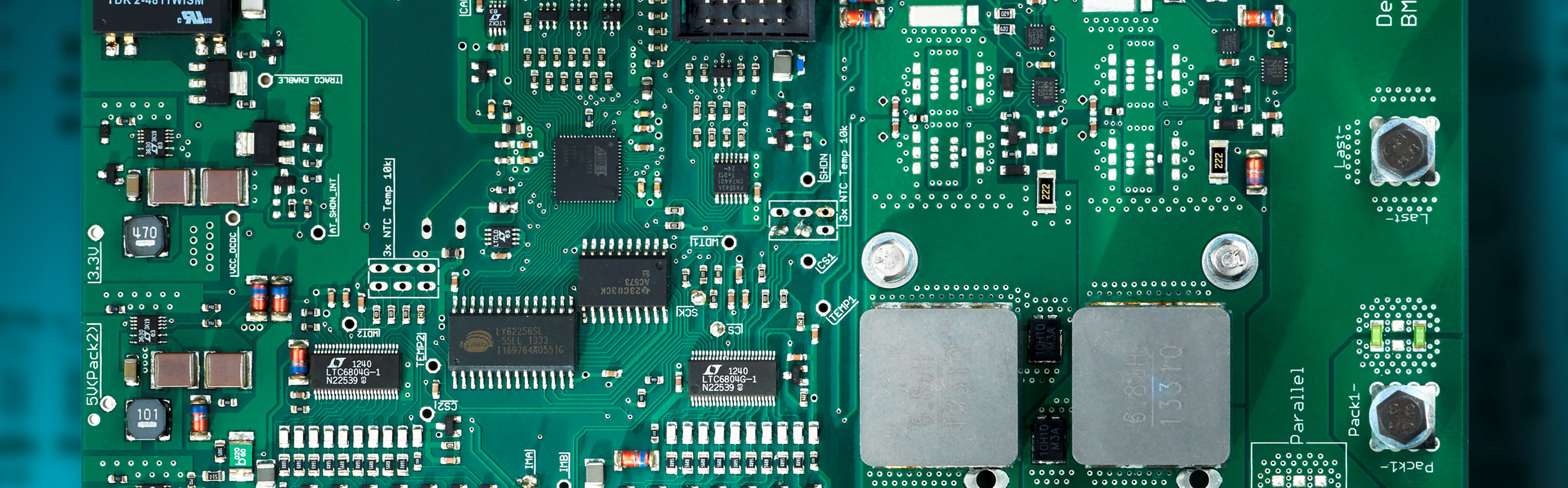

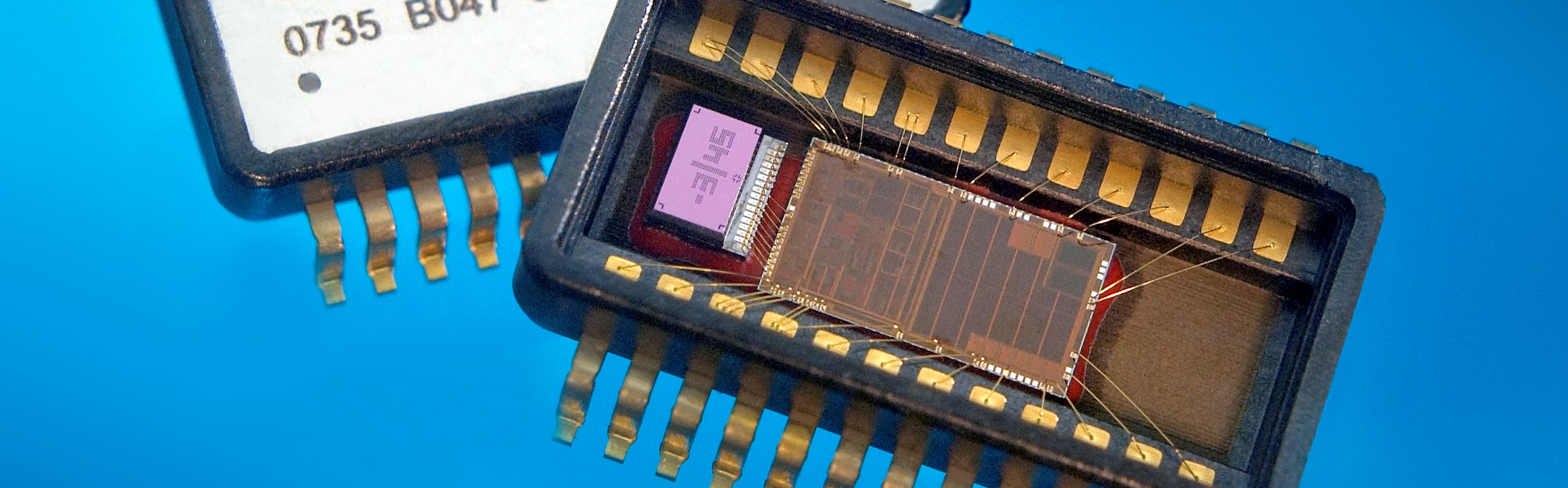

The module integration deals with the chip's way from the wafer to the final product, starting with back-end technologies such as grinding and dicing to the stress controlled assembly of ultra-thin dies up to MEMS-modules and power modules.

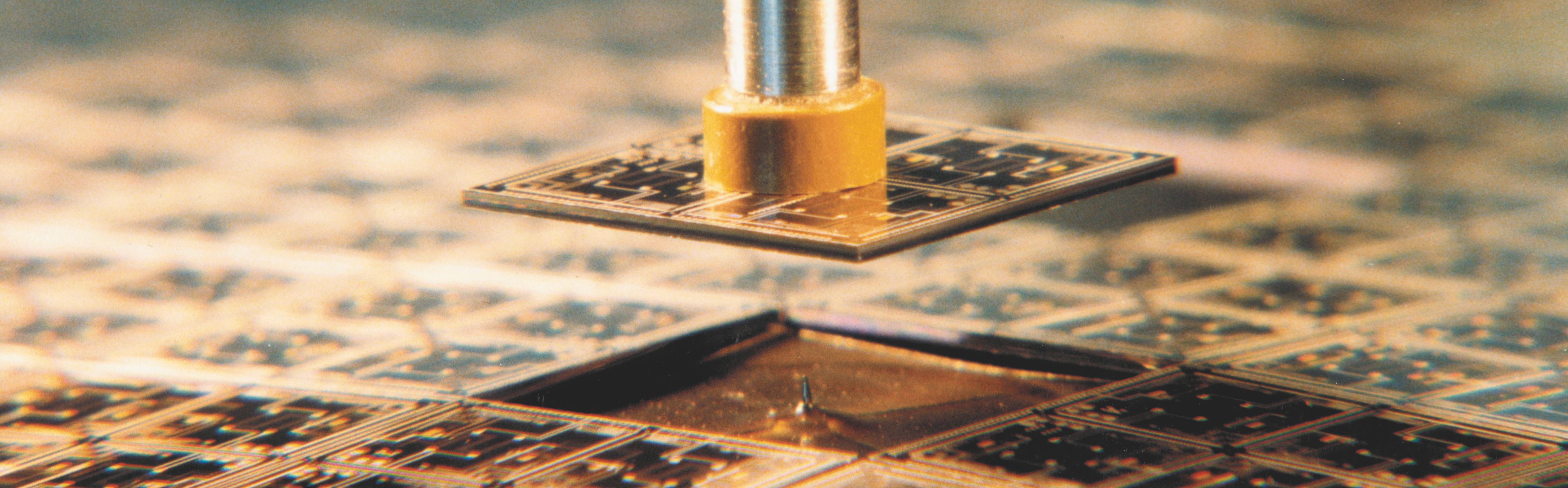

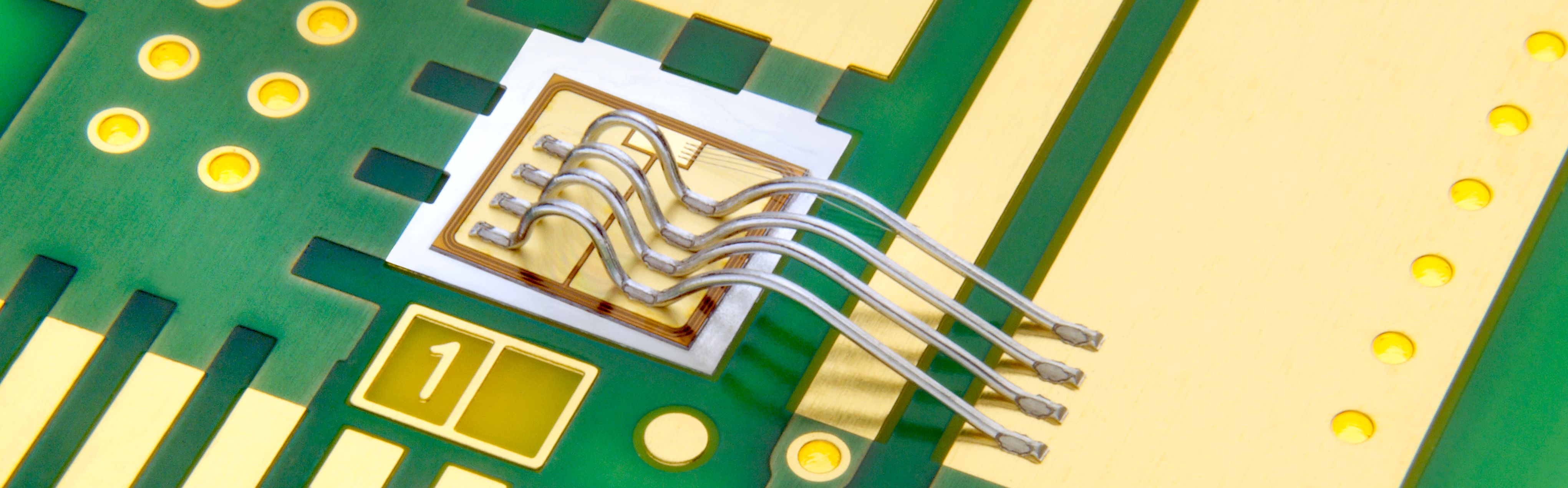

The current research topic is the precision assembly of pre tested components on a wafer. Using silicon or glass wafers as substrates it is possible to construct low-stress assemblies, which can be further processed as a wafer after component assembly. Through the following wafer balling process compact multichip modules result which can be used as a chip size package directly.

For optical applications lenses and laser diodes various wavelengths shall get integrated on a substrate and sealed using wafer-level packaging with a cap made of glass.

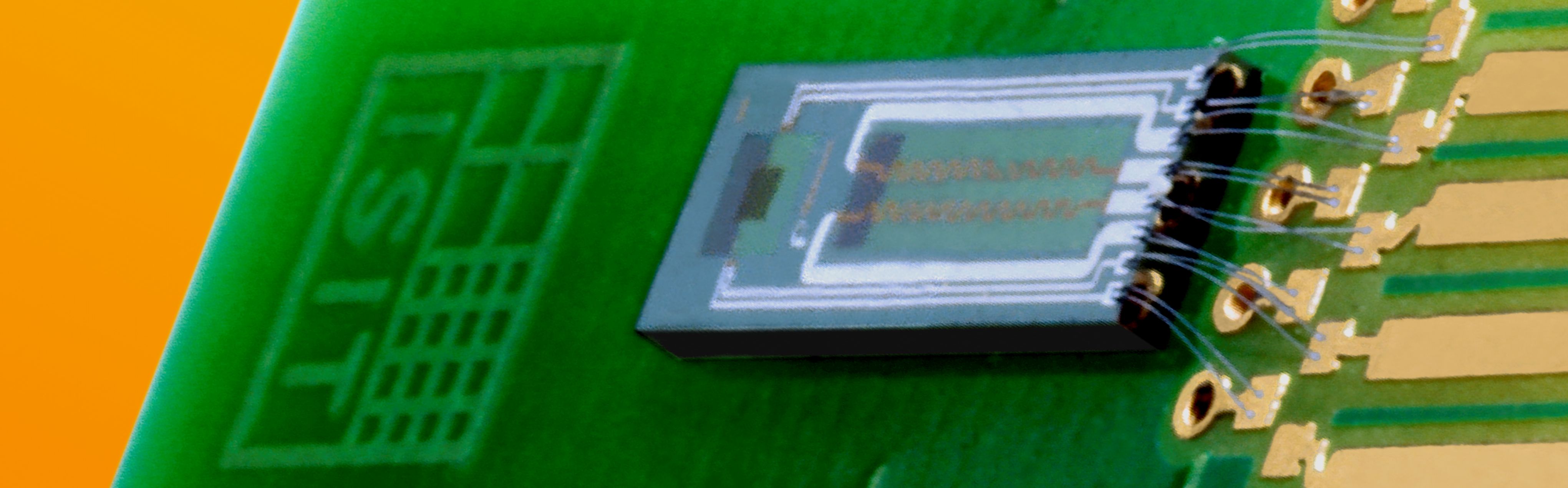

ISIT also gives advice to customers regarding the planning of multichip modules or system-in-package solutions. On demand, ISIT provides test chips and substrates from the existing portfolio or as an individually adapted solution. Furthermore, Fraunhofer ISIT actively promotes new process technologies, be it as an exclusive development partner or by acquisition of public funding on a national or European level, e.g. to foster SME research or international cooperation.

Current research projects:

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology