Modular multilevel converter (MMC)

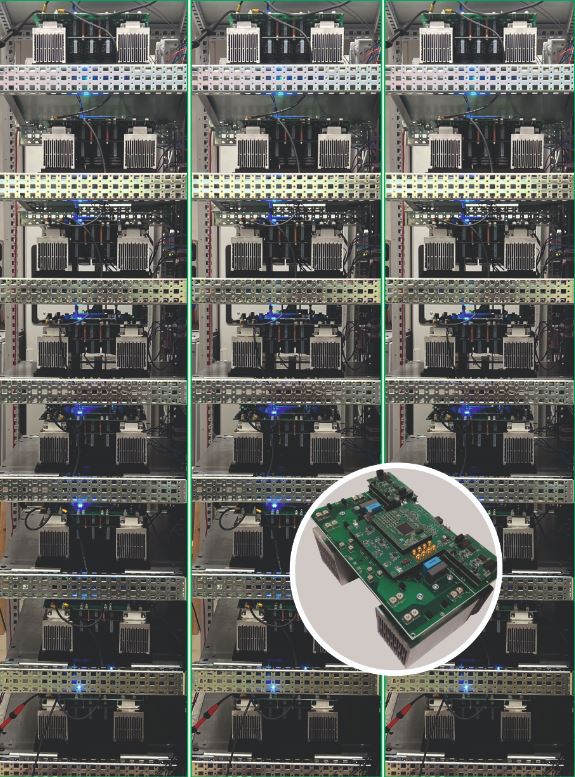

Modular Multilevel Converters (MMCs) are a type of power electronic converter used for medium- and high- voltage direct current convertion, consisting of a multitude (up to several hundreds) of series-connected sub-modules of relatively low voltage rating. This topology creates multiple output voltage levels, providing improved efficiency and voltage control in high-power electrical systems.

MMCs are a key technology in driving the energy transition of our society, providing improved efficiency, power quality, fault-tolerance and higher power density. The ability to operate in different voltage ranges makes such technology essential for the development of both AC and DC grids. By leveraging the capabilities of MMC technology, we can shape the energy systems for a sustainable future.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology