Research & Development

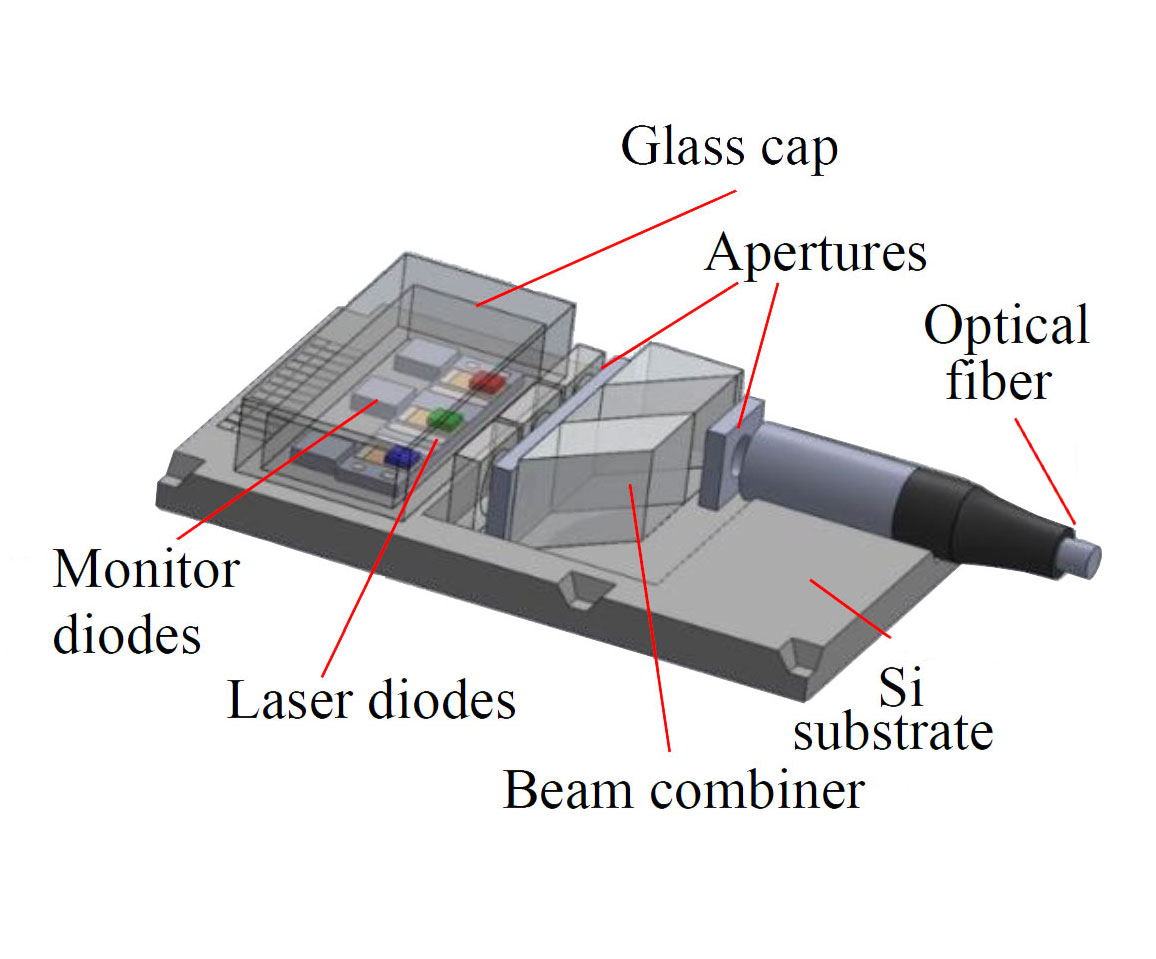

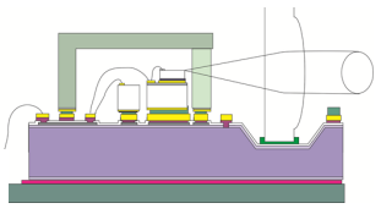

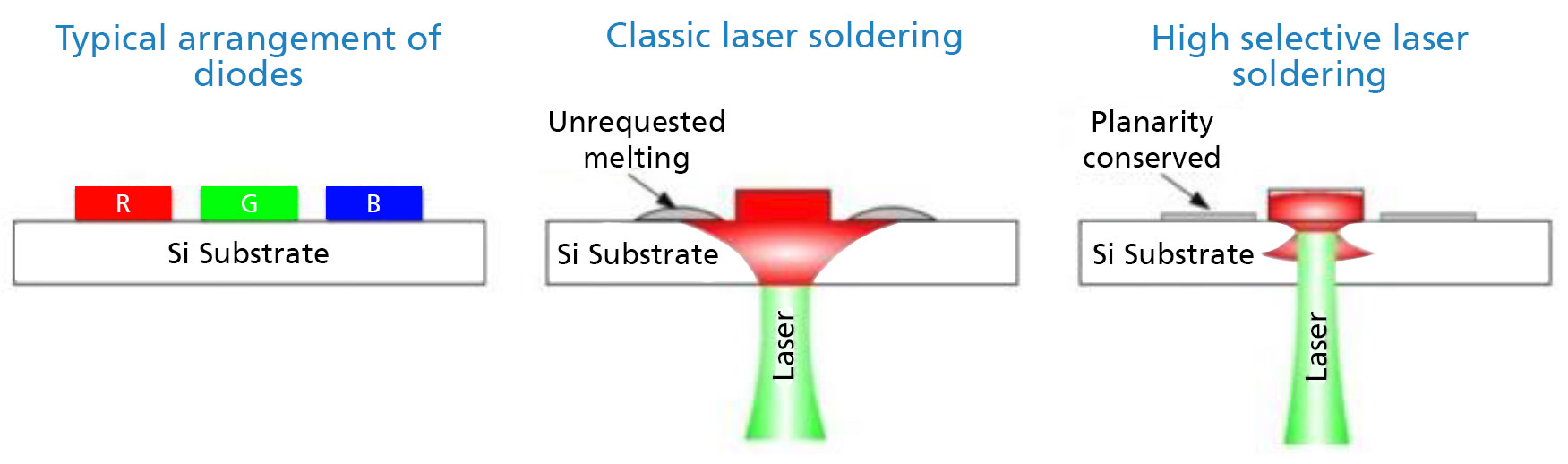

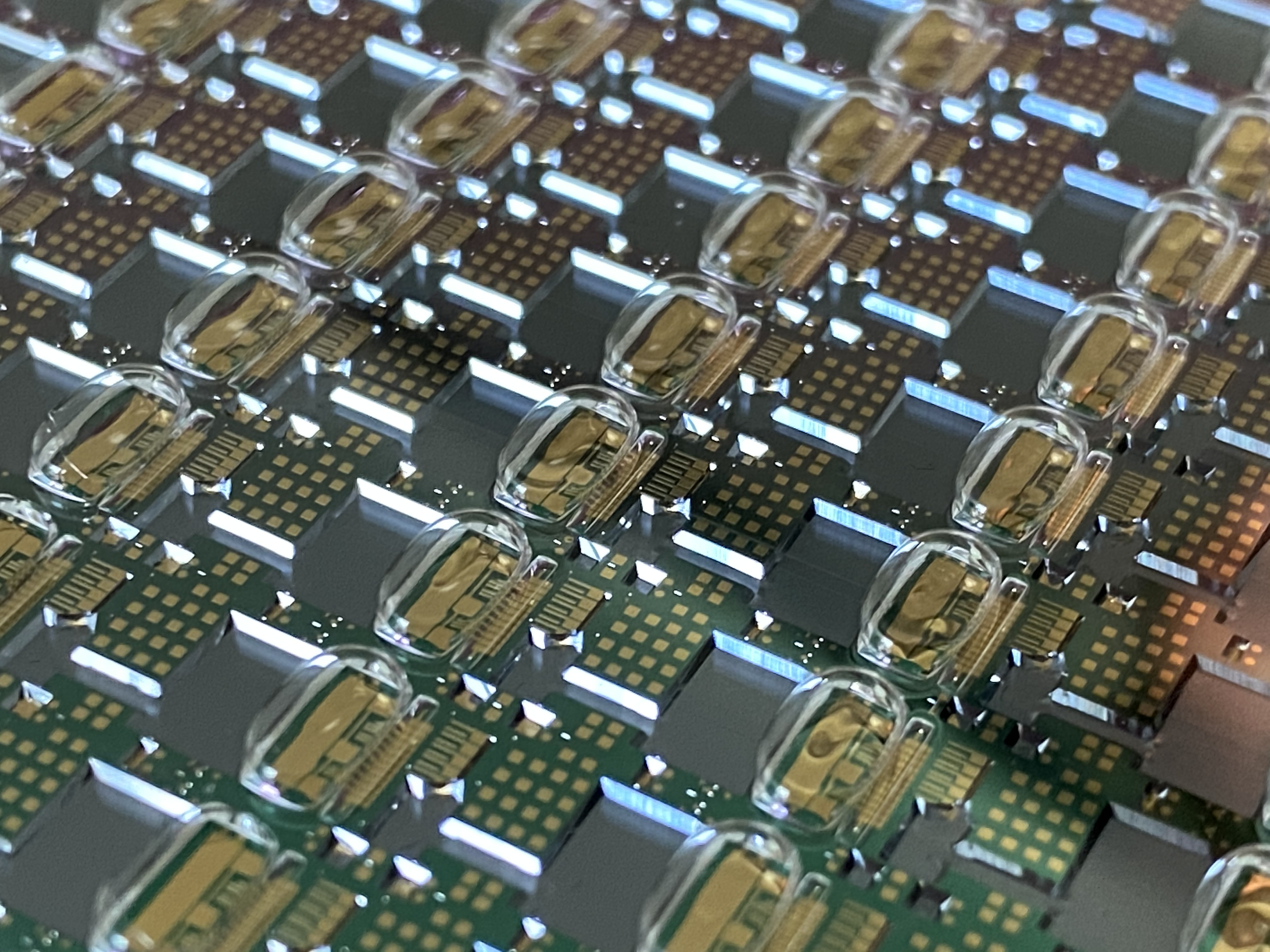

Based on our MEMS wafer processes, we developed an optical bench silicon chip where all laser components and the diode laser chips are assembled. For diode chips we use a specially developed solder process with low thermal impact. The assembly and wire bond interconnection can be performed on single substrates, panels and 200 mm wafer.

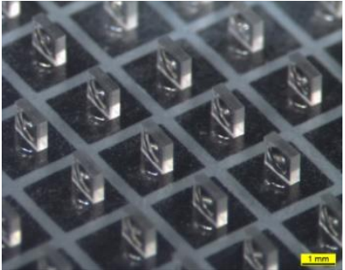

Silicon here provides the required stability of an optical bench. A precision assembly machine configured with in-situ laser soldering and active lens adjust provides the required infrastructure to realize new optical constructions and produce demonstrators, such as a multi-channel laser light source.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology