With structured metal-coated polymer film to produce affordable biosensors

Churning out biosensors

The Fraunhofer Institute for Silicon Technology ISIT and the Fraunhofer Institute for Organic Electronics, Electron Beam and Plasma Technology FEP have successfully developed and tested flexible electrochemical biosensors on metallized film substrates.

The growing market for wearable devices requires a high number of small, light-weight and high capacity sensors for different applications in sport, medicine or at work. Especially useful are so-called “wearables” such as functional wristbands which provide practical assistance while barely being felt. These devices can monitor body function and provide valuable information. In addition, the electronics should adhere flexibly to the arm.

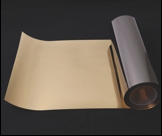

Fraunhofer researchers have now succeeded in taking a crucial step on the way to the production of such forward-looking products. Within the Fraunhofer ISIT the business fields “Medical Sensor Systems “ and “Wearables and Printed Electronics” cooperate in investigating how silicon-based sensor technologies can transfer to flexible modules and integrate into body-shape sensor systems. The Fraunhofer FEP has considerably advanced this development by providing metallized film substrates, with the Fraunhofer ISIT developing a flexible electrochemical sensor with which good results could be attained. The Fraunhofer FEP has the technology to provide polymer films with a thin metal layer, which is based on a roll-to-roll process. A high degree of uniformity of the layer‘s thickness and a lack of defects represent particular technological challenges in this manufacturing process.

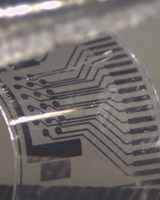

The sensor measures 8 x 10 mm² and contains an array of electrodes for biological immunological tests. The special feature: the sensor’s thickness is only approximately one tenth of a millimeter as it was produced entirely on a polymer film which had previously been coated at the Fraunhofer FEP. The fundamental principle for the production of flexible sensors are thin layers in the submicrometer range. The researchers at the Fraunhofer FEP have a lot of experience in coating polymer films without defects and with a high degree of uniformity in highly productive roll-to-roll processes.

Christopher Beale, who developed the sensor as part of his Master’s thesis at the Fraunhofer ISIT, is pleased: “Our flexible electrochemical biochip shows similar results in a first test series when compared to our silicon chip.”

“Polymer films are especially well suited for such applications as they are light weight, flexible and biocompatible,” adds Dr. Matthias Fahland. “The results are encouraging even if some hurdles must be overcome still in order for such biosensors to be produced affordably in roll-to-roll processes. We at the Fraunhofer FEP with our processes and facilities are ideally positioned for further research in this promising field. ”

Both institutes will work together more closely in the future in order to develop tailor made flexible electronics for the products of the future together with customers from industry. There are for example developments to integrate polymer films-based lactate sensors in wristbands. Thus it would be possible to monitor the wearer’s fatigue during exercise through correlated lactate concentration in sweat.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology