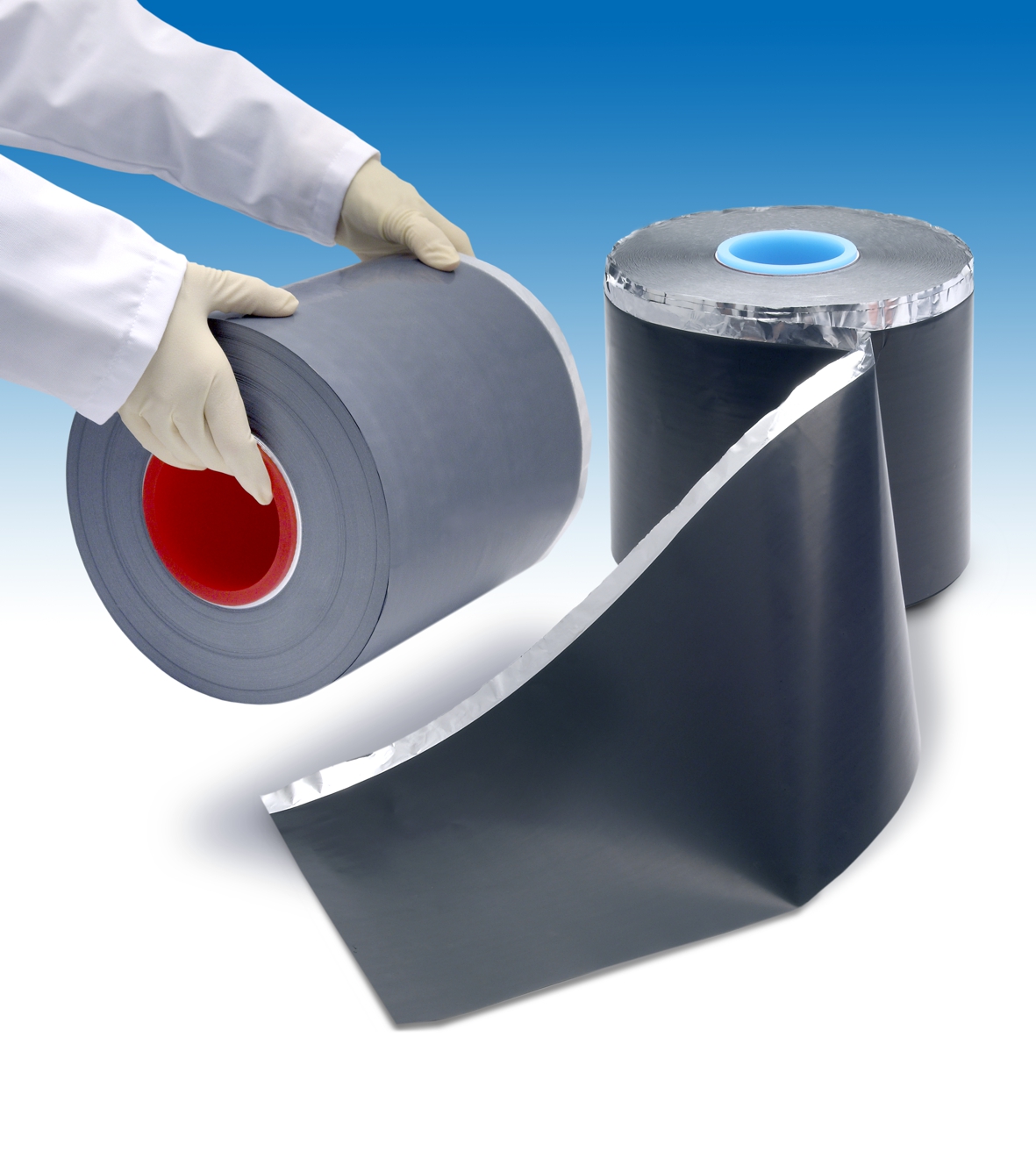

The production of high-strength electrodes is a promising approach to increasing the energy density of Li-ion batteries, as they have a favorable ratio between active and inactive materials. However, modern tape casting processes with relatively high solvent content are limited in terms of layer thickness and drying process, which is associated with undesirable effects such as binder migration. Therefore, advanced processes for electrode production are urgently needed.

Fraunhofer ISIT has developed a dry coating process that works completely without solvents. Drying the coated electrode sludge is an energy-intensive process. It also requires a large amount of space, as long drying distances are necessary for optimum process results. The dry coating process developed by Fraunhofer ISIT makes the use of solvents superfluous. In addition, higher loads are possible that exceed the range of conventional electrodes. This leads to considerable cost savings and is more environmentally friendly.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology