Research & Development

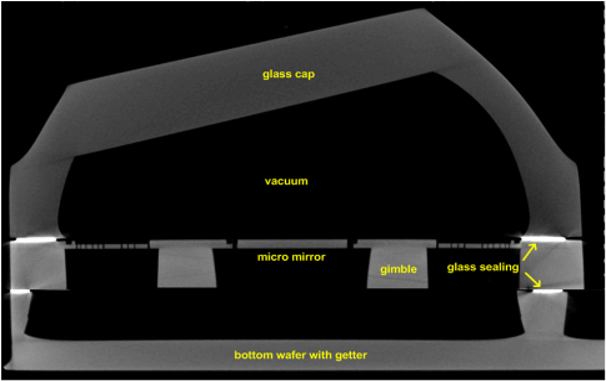

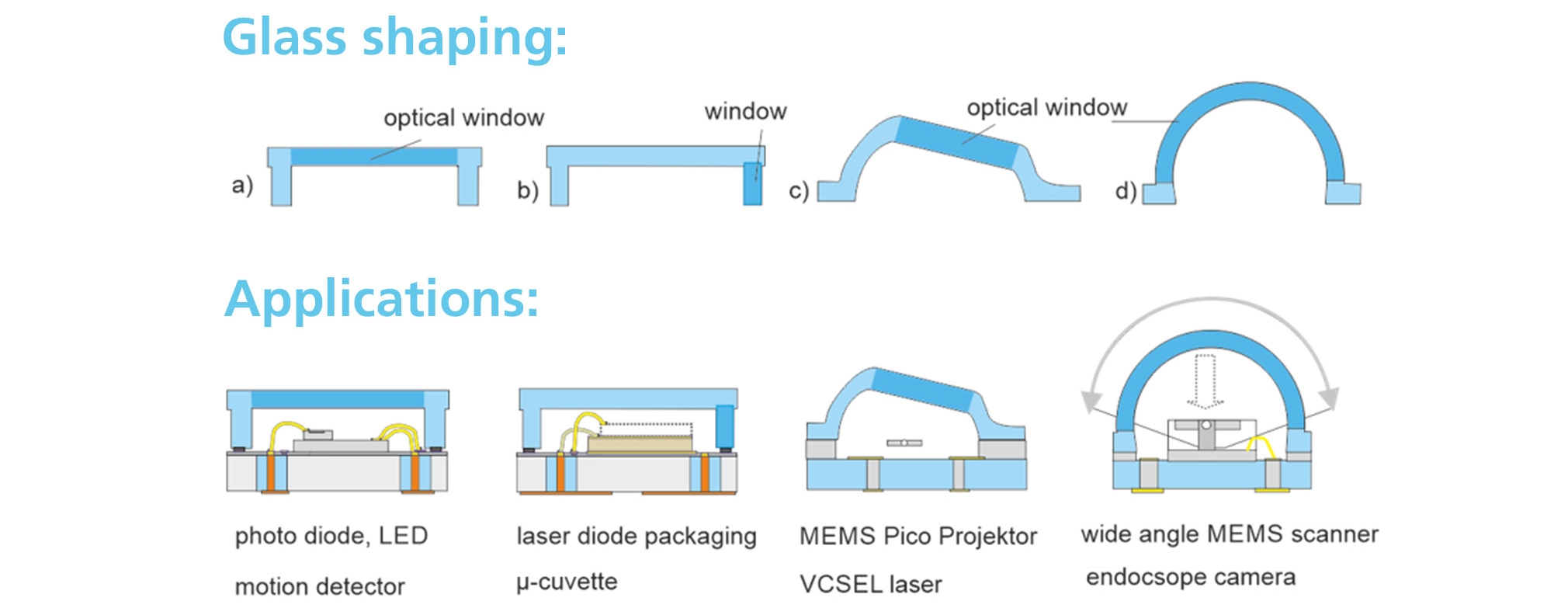

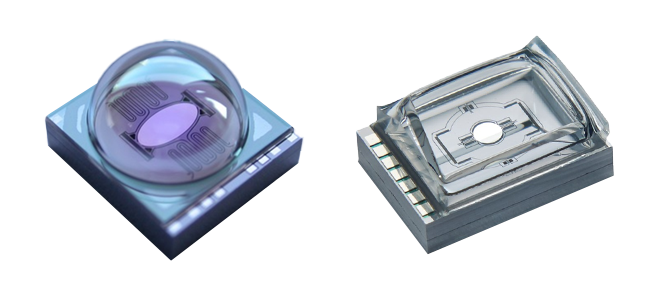

The basis for our hermetic glass capping is our patented glass flow technology. Combined Silicon and glass substrates as well as several etch and patterning technologies come here into play.

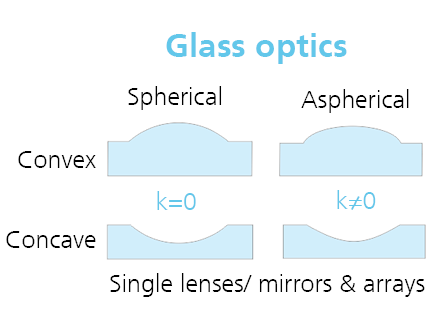

With this technology we manufacture new components made of glass at wafer level. Without further processing we now can manufacture micro lenses, reflectors, prisms and other specially shaped optical windows or parts in large numbers at wafer level. This enables an economical low/high volume production of micro optical components for your application.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology