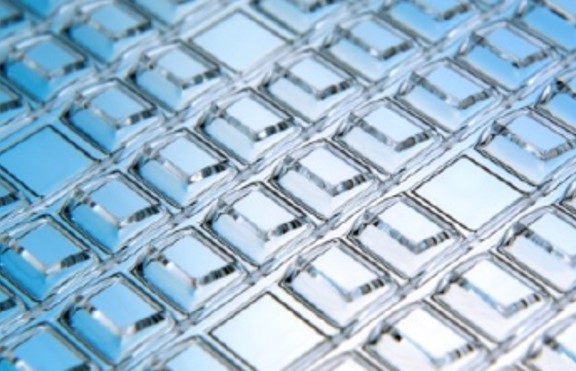

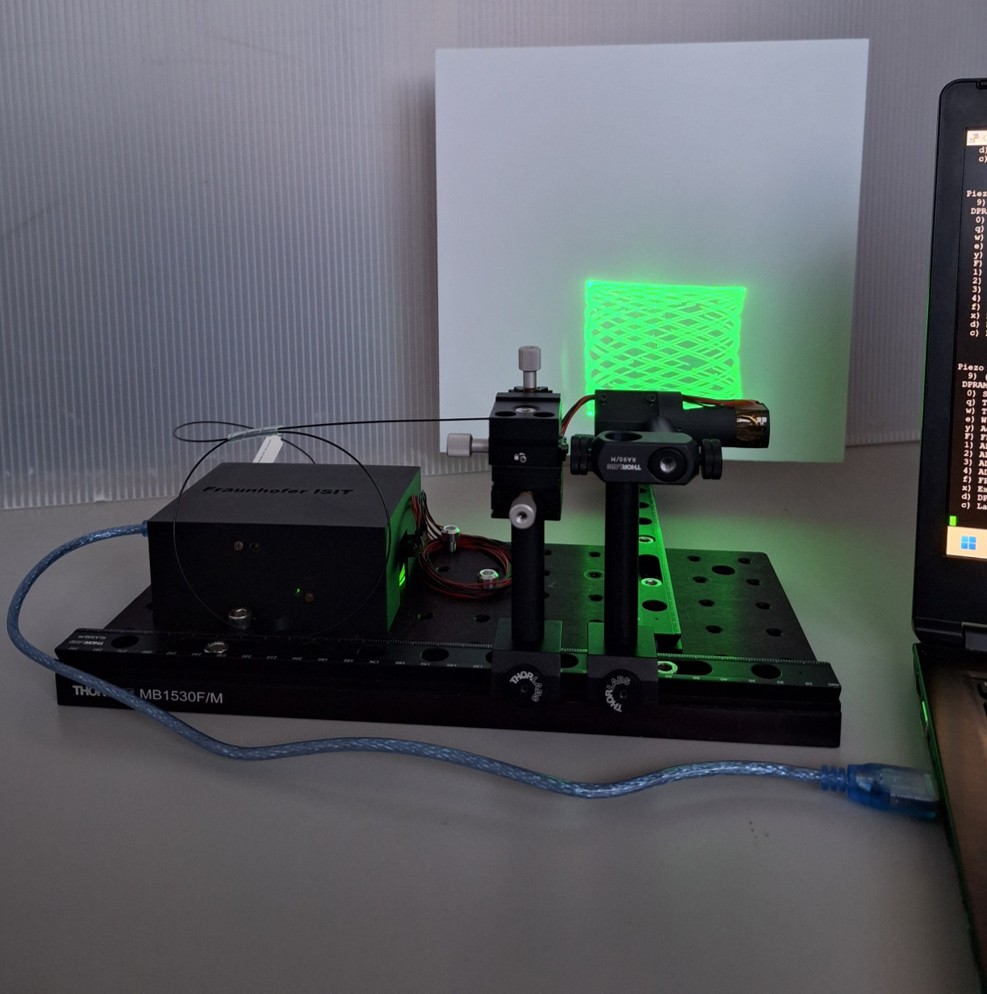

At the trade fair, visitors will receive comprehensive information on hot viscous molding, an innovative process in micro-manufacturing. This process enables the precise production of micro-components by heating viscous materials, which are then molded. Particularly noteworthy is a newly developed process at Fraunhofer ISIT based on the hot viscous molding of glass. With the help of this process, it is possible to structure glass wafers with high aspect ratios at wafer level in such a way that the good optical properties are retained.

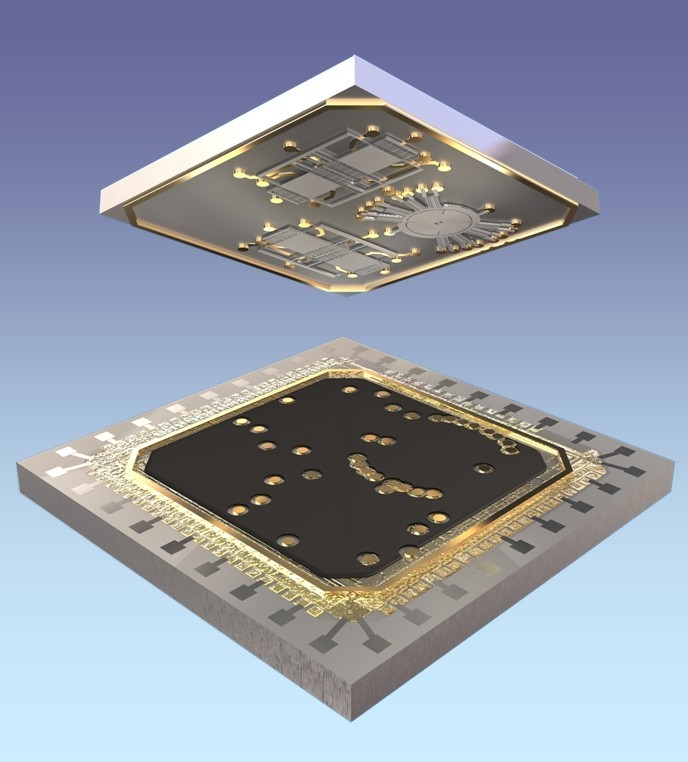

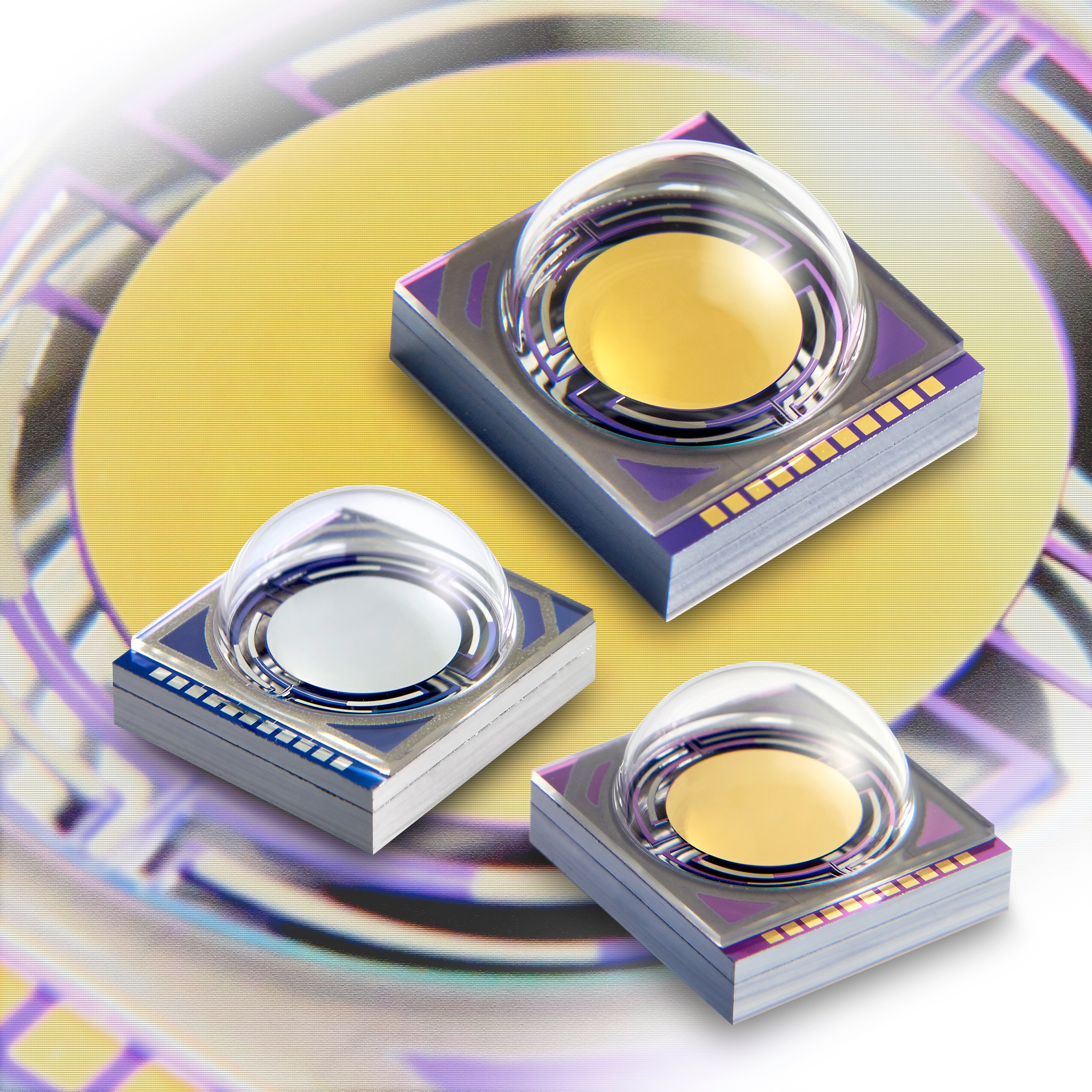

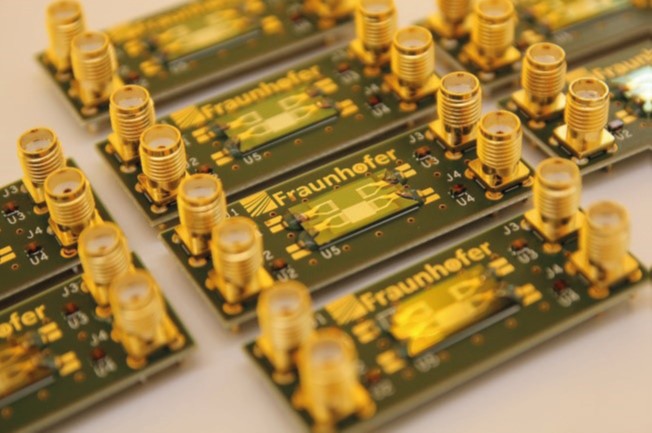

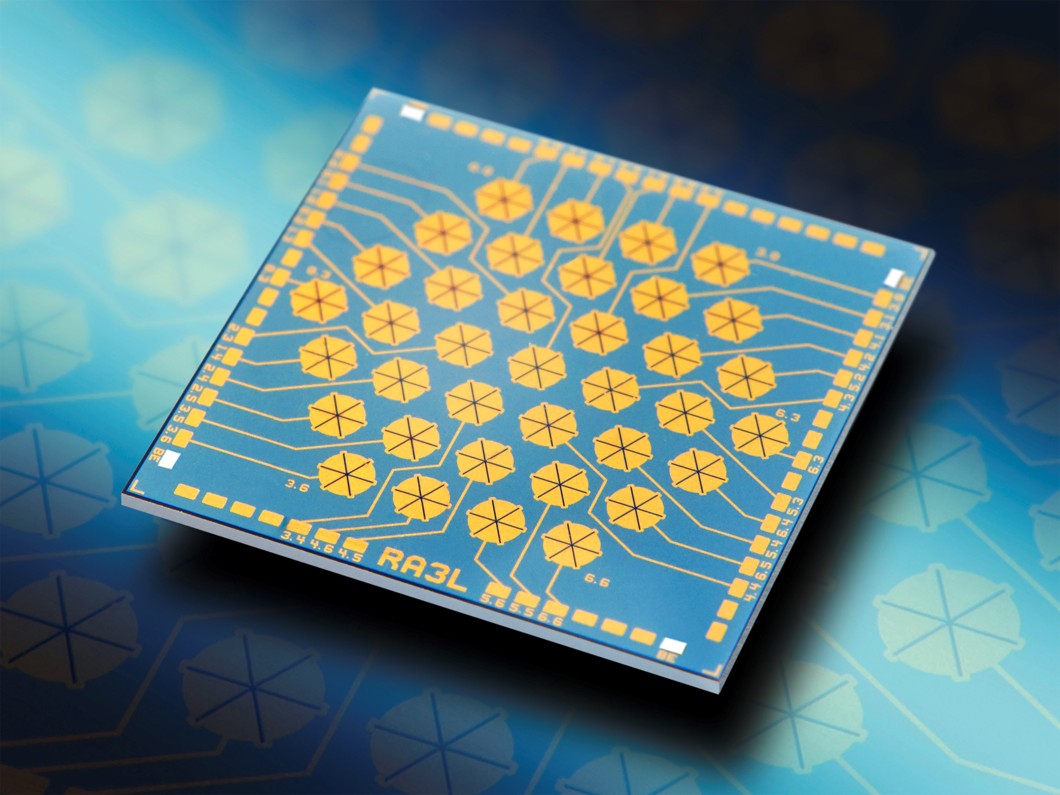

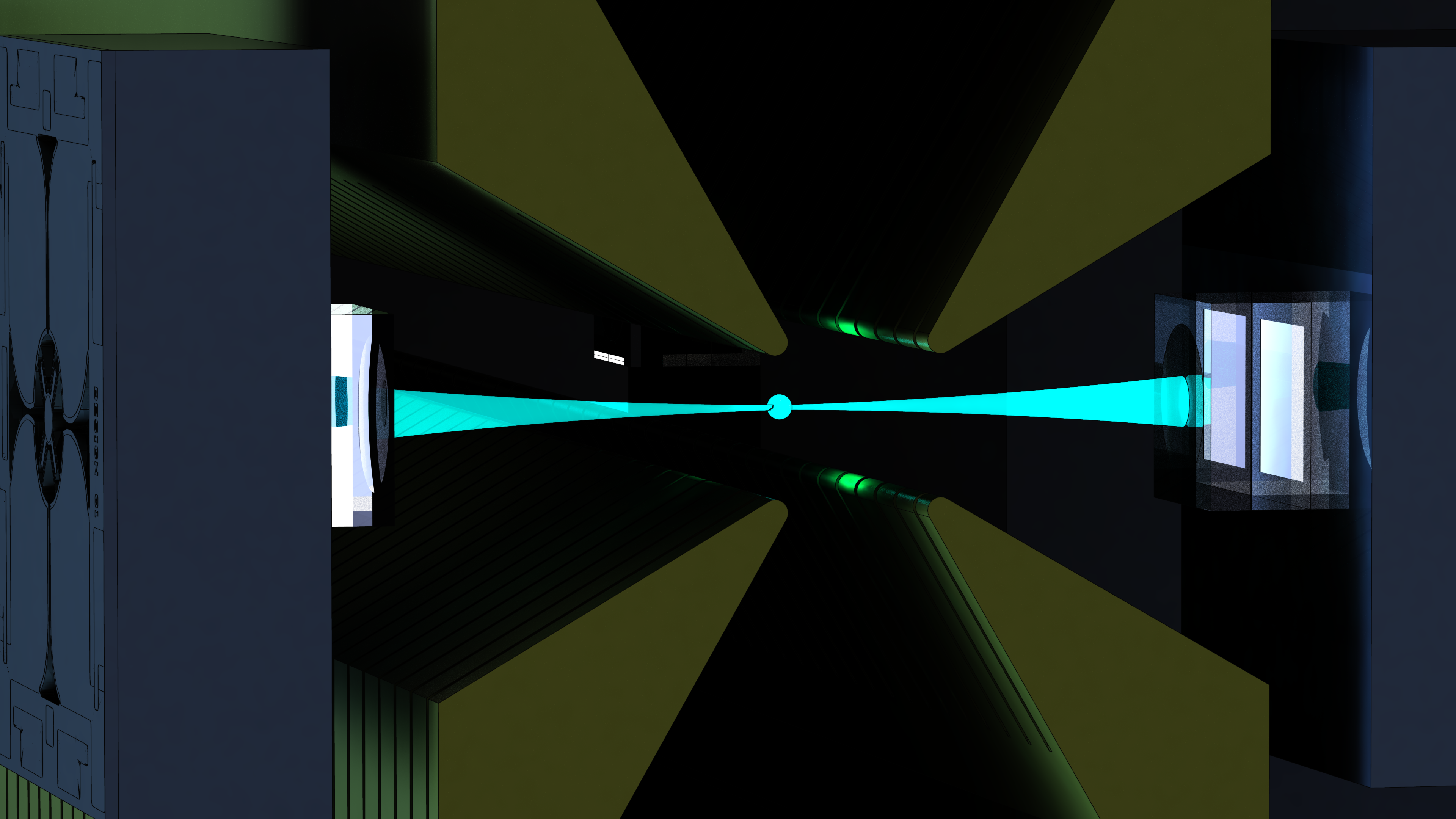

With the help of this unique technology, new components can be manufactured from glass at wafer level for the first time that meet the qualitative requirements of optics. This means that microlenses, reflectors and specially shaped optical windows can be produced in large quantities at wafer level without further mechanical processing, enabling cost-effective mass production of micro-optical components (wafers with gold-plated concave mirrors). In combination with MEMS scanners and active optical components, this manufacturing process is the key to hermetically encapsulated MEMS components that meet the high requirements of optical functionality (MEMS mirrors with inclined windows).

Visitors can also find out about the specific steps of the hot viscous molding process, discover application examples in the microelectronics and semiconductor industries and learn about current research projects and innovative developments. In addition, opportunities for cooperation in research projects will be discussed, which could be of great interest to interested partners.

More Info

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology