First high-performance, integrated MEMS loudspeakers for high-quality speech and music reproduction

Successful presentation of the newest MEMS loudspeaker technology at this year´s DAGA-Conference

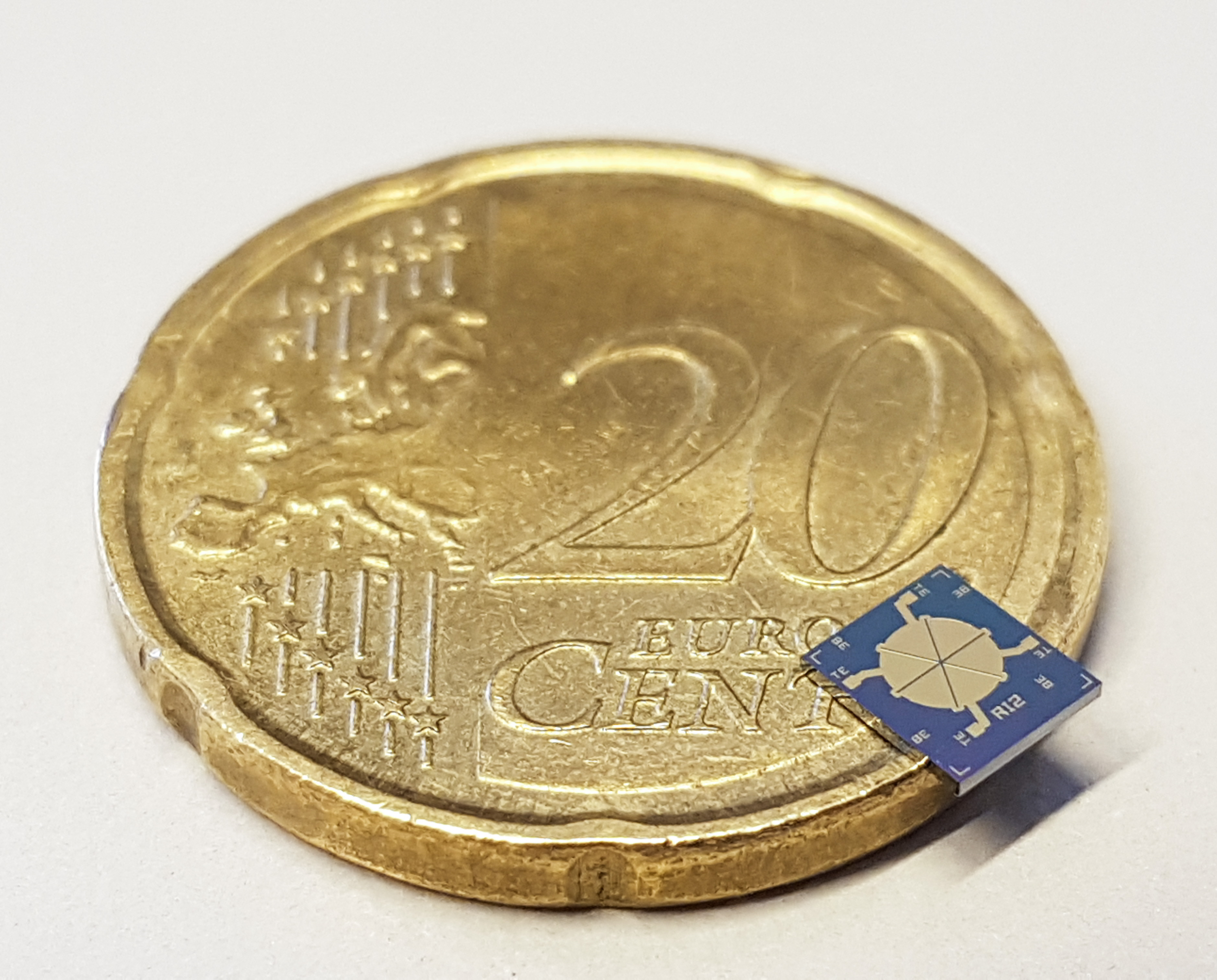

The German Fraunhofer Institutes for Silicon Technology ISIT and for Digital Media Technology IDMT caused a stir at the Jahrestagung für Akustik DAGA (the annual conference of the German society for acoustics) in Munich from March 19 to 22, 2018. They presented the first integrated MEMS-based micro speakers to industry representatives and experts. The MEMS speakers will be used in future mobile communication devices, headphones, and hearing aids. With an area of just 4x4 millimeters, they cover the complete frequency range from 20 Hz to 20 kHz as a one-way system and achieve a sound pressure level of 110 dB for in-ear applications.

MEMS stands for microelectromechanical systems and combines classical semiconductor technology with precision mechanics in the micrometer range. With this new approach, the two research institutions are heralding a paradigm shift. From now on, loudspeakers can be made of silicon just like computer chips.

Over the last three years, both Fraunhofer Institutes have been cooperating in the joint research project "Smart Speaker - Smart MEMS speakers for mobile applications" on the development of energy-efficient and completely integrable chip-based loudspeakers. While Fraunhofer ISIT is responsible for the development and pilot production of piezoelectric microactuators and their integration into highly miniaturized intelligent microsystems, Fraunhofer IDMT deals with intelligent signal processing for micro speaker control.

Technological breakthrough for micro speakers

Now, they have achieved a new breakthrough and the impressive features of the chip-based loudspeaker have been presented to industry representatives and experts. With a current area of 4x4 millimeters and a chip thickness of just 0.4 millimeters, the MEMS loudspeakers can be optimally integrated into headphones, hearables, and hearing aids. Still, despite their small size, the presented MEMS speakers offer high fidelity and low power consumption, which is particularly relevant for battery-powered devices. Moreover, the production with silicon technology enables extremely cost-efficient and precise mass production.

Positive Feedback from the industry

At the annual DAGA conference, the two research institutes demonstrated their integrated MEMS speaker technology with in-ear headphones and received a very positive response from the industry and the scientific community. "The powerful, balanced sound and the outstanding brilliance in the high frequency range were particularly praised," explains Fabian Stoppel, project manager and head of the group for acoustic MEMS at Fraunhofer ISIT.

The coordinator for the entire project, Prof. Bernhard Wagner of Fraunhofer ISIT, is also convinced of the high performance of the acoustic microsystems and sees the positive feedback from the industry as confirmation: "Our loudspeakers for hearing aids, in-ear headphones and hearables already meet market requirements. They already cover more than the usual frequency range from 20 Hz to 20 kHz, can manage with just 1-2 volts, and have high power reserves," says Wagner.

Next steps: Increased performance, even smaller size, new applications and customization for mass production

The first big success has been achieved, and the institutes are now further optimizing the MEMS speaker for use in in-ear headphones and are working on speakers for devices that are further away from the ear, such as mobile phones, tablets, and laptops. Therefore, one goal is to achieve even better acoustic performance. In addition, the transmission bandwidth is to be expanded to over 40 kHz by implementing integrated multi-way systems. "This puts us in a position to meet the high quality demands of the headphone market (e.g. high-resolution audio)," says Dr. Daniel Beer, project manager and group leader for Electroacoustics at Fraunhofer IDMT. Fraunhofer ISIT is currently developing loudspeakers based on new piezoelectric materials that are even more energy-efficient and CMOS-compatible. This further reduces power consumption and enables mass production of MEMS loudspeakers in all major semiconductor factories. The institute is also working on further reducing the size of the micro speakers, opening up new fields of application and making chip loudspeakers attractive for use in the low-cost segment.

How does the MEMS loudspeaker principle of Fraunhofer ISIT and IDMT work?

Piezoelectric thin films on silicon are used as active elements that deform when electrical voltage is applied (so-called flexural mode resonators). This mechanical deflection displaces the surrounding air and thus generates sound. Modern chip manufacturing technologies are ideally suited for the fabrication of smallest structures and enable completely new loudspeaker concepts.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology