von Magdalena Kontek

12" thin wire bonder installed at ISIT

In February of this year I had the pleasure to start up a new fully automatic thin wire bonder Bondjet 855 from Hesse mechatronics. I would like to share my experiences with you in this TechBlog article!

Customized device

This is not an ordinary off-the-shelf machine, but a device I was looking forward to for a long time, as it was modified according to the wishes of ISIT. On the one hand I was very curious about the way the machine works, because the software is completely different from the previous models, and on the other hand I was curious about the new working possibilities in general, which should open up to me through our specific modifications. And of course I wanted to see how fast the latest wire bonder is, and one thing I can assure you, it is darn fast!

At this point I would like to introduce the machine to you

Its model name is Bondjet 855 and it is a fully automatic thin wire bonder from Hesse mechatronics. It is slightly larger than a household refrigerator and freezer and a little heavier. Different bond heads can be mounted, which are optimized for the respective task. We have a standard bond head with a 45° clamp, as the name "standard" suggests, this is normally used and most setups can be realized with it without problems. However, there are exceptions, such as very low lying components, high edges of the case or very little space in the setup, here the "standard" bond head reaches its limits. In order to wire-bond these more complex samples, we also have a "deep-access" bond head. This has a slightly different structure from tool to wire clamp and is therefore able to process such "difficult" components. As I already mentioned above, the machine is very fast and can realize up to 7 bond connections per SECOND under good working conditions. Believe me, this is fast!

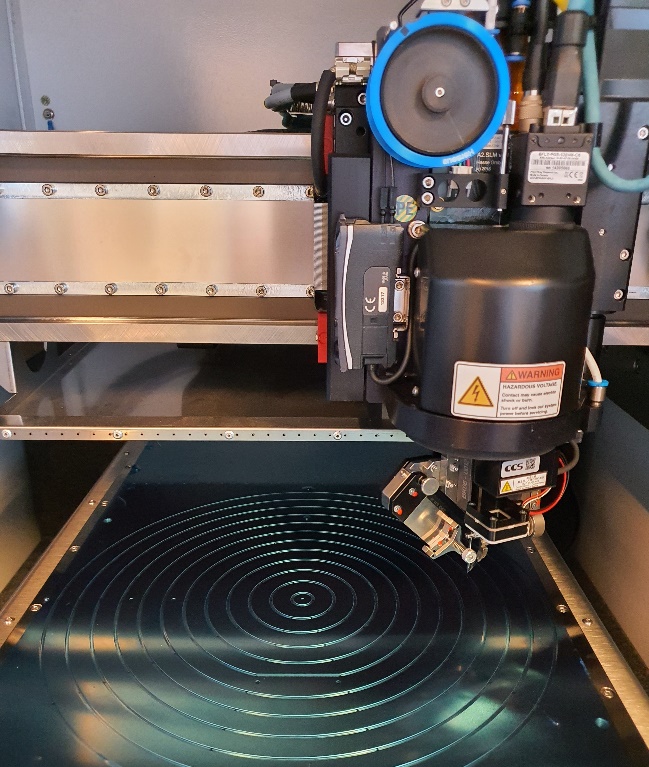

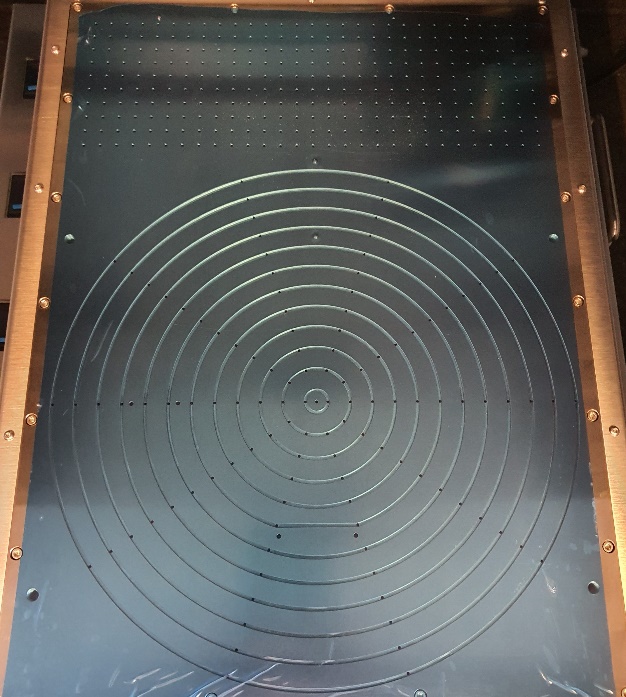

Modified work table - The Future is Now

But that was now all the usual accessories, nothing unusual, but our modified work table is not ordinary. With it we are able to suck in wafers up to 12" in size with vacuum, heat them and process them completely without having to move them! The "wafer table" has 3 working areas where the machine automatically detects the wafer size and can switch the vacuum separately. Each wafer size is thus ready for programming and processing at the push of a button without any conversion! So that boards, ceramics and individual components can also be taught and bonded on this great machine, it also has a large, rectangular working area with suction holes that have a small distance between them and can therefore hold the flat samples well.

With its exceptional worktable, the Bondjet 855 can handle many different substrates, but there's more to it than that. Since the machine table is heatable, a wide variety of wire and tape materials can be used. Typical are: Gold, copper, silver and platinum wires as well as aluminum and gold ribbons, but if you want to try something else with us, please contact us!

Author: Magdalena Kontek

This might also be of interest to you

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology