Also this year Fraunhofer ISIT presents itself at Photonics West in San Francisco. Under the heading "Micro Actuators for Optical Applications" we offer information and offers on three different topics.

Laser material processing

High power laser scanner (with stroboscope illumination)

Laser material processing, laser welding, laser cutting etc.

The new MEMS scanners developed by Fraunhofer ISIT allow the fast deflection of laser radiation with up to 4.5 kWatt at scan frequencies in the kilohertz range. This allows a significant increase in throughput for many manufacturing processes and, in many cases, new functionality and quality enhancements. Dielectrically coated, highly reflective mirrors with apertures of up to 20 mm are unique worldwide.

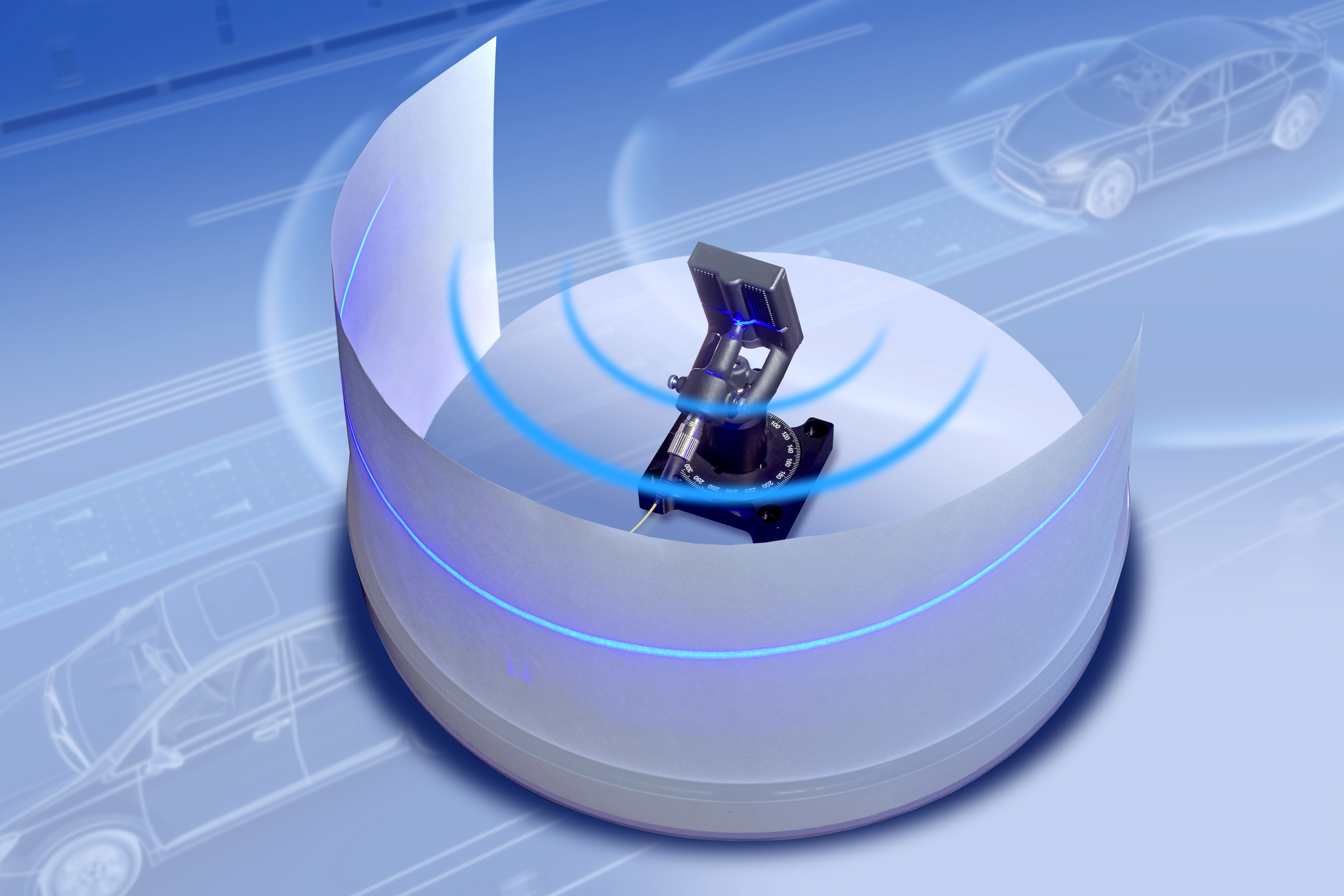

MEMS LIDAR Systems

LIDAR Systems / 3D Camera

The 3D camera is based on a 2D MEMS scanner that uses the principle of the phase difference of an emitted laser beam to the detected "echo" as a distance measurement. The phase detection algorithm allows 60 million 3D measurements per second. The camera has a resolution of 450 x 450 pixels and delivers six images per second. The depth resolution is said to be a few millimeters and the maximum detectable distance to the object is 2 m.

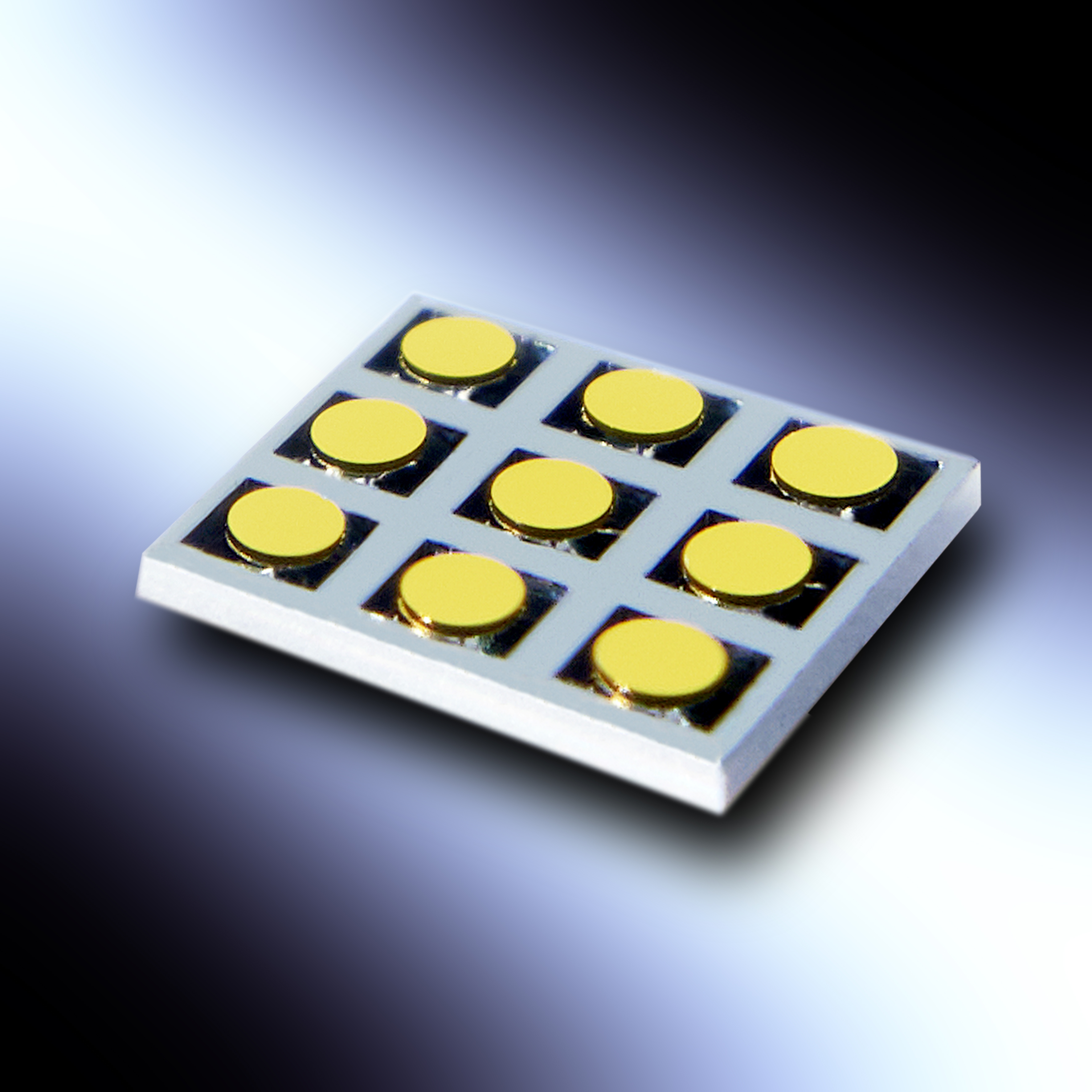

Opto-Packages

Glass Packages for Wafer-Level Packaging

Development of remolded glass wafers to achieve specially adapted optical functions. Based on a glass wafer reshaping technique developed and patented by Fraunhofer ISIT, microlenses, reflectors and specially shaped optical windows can be mass-produced at wafer level, enabling low-cost mass production of micro-optical devices. In the context of MEMS scanners and IR MEMS devices, this manufacturing process is the key to hermetically encapsulated MEMS devices with optimal optical functionality.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology