With the FlaMe research project, the project partners want to address the industry's requirements to be able to produce customer-specific power modules at small batch sizes economically, with high quality as well as energy-efficiently.

FlaMe - Flexible customized manufacturing of power modules

Highly flexible, fully automated production

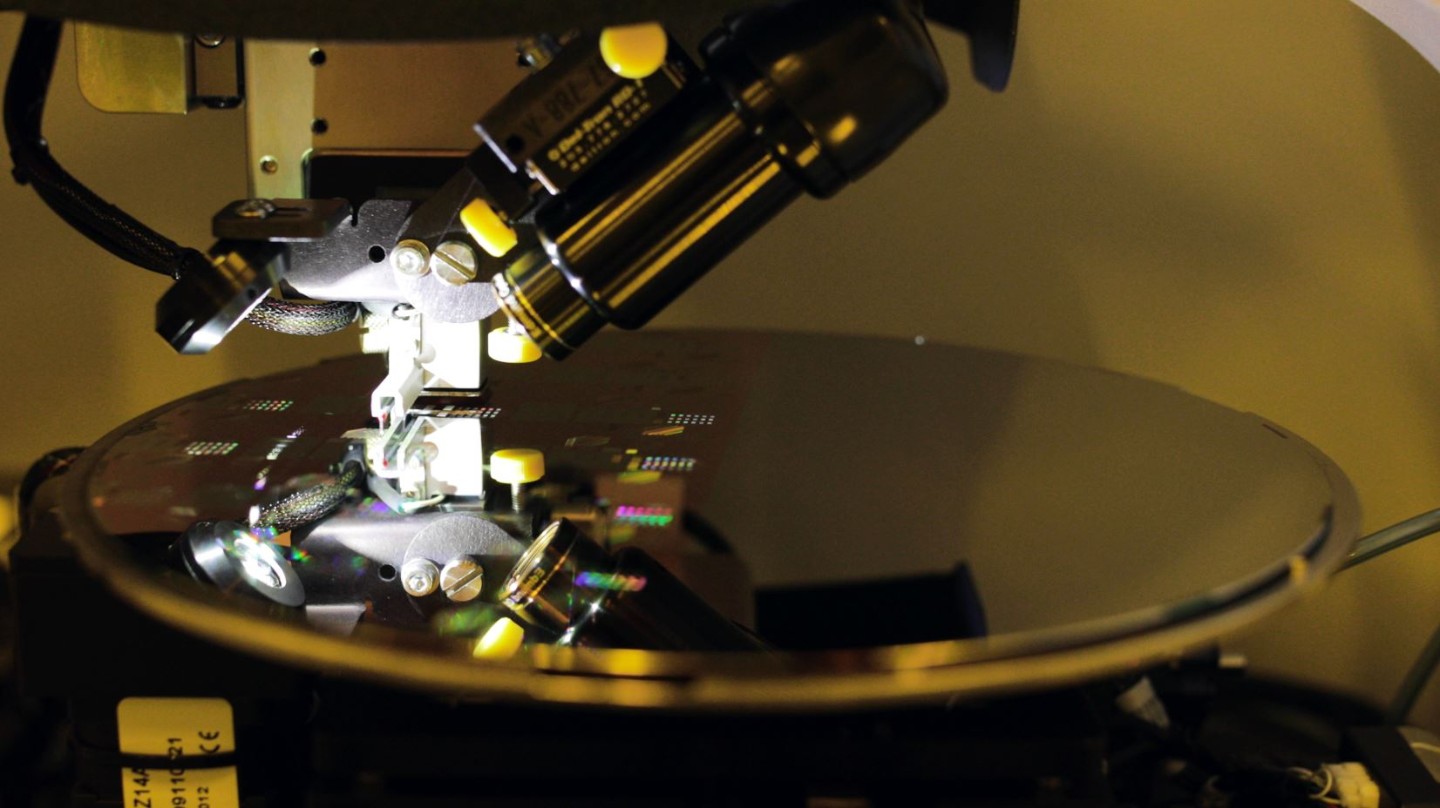

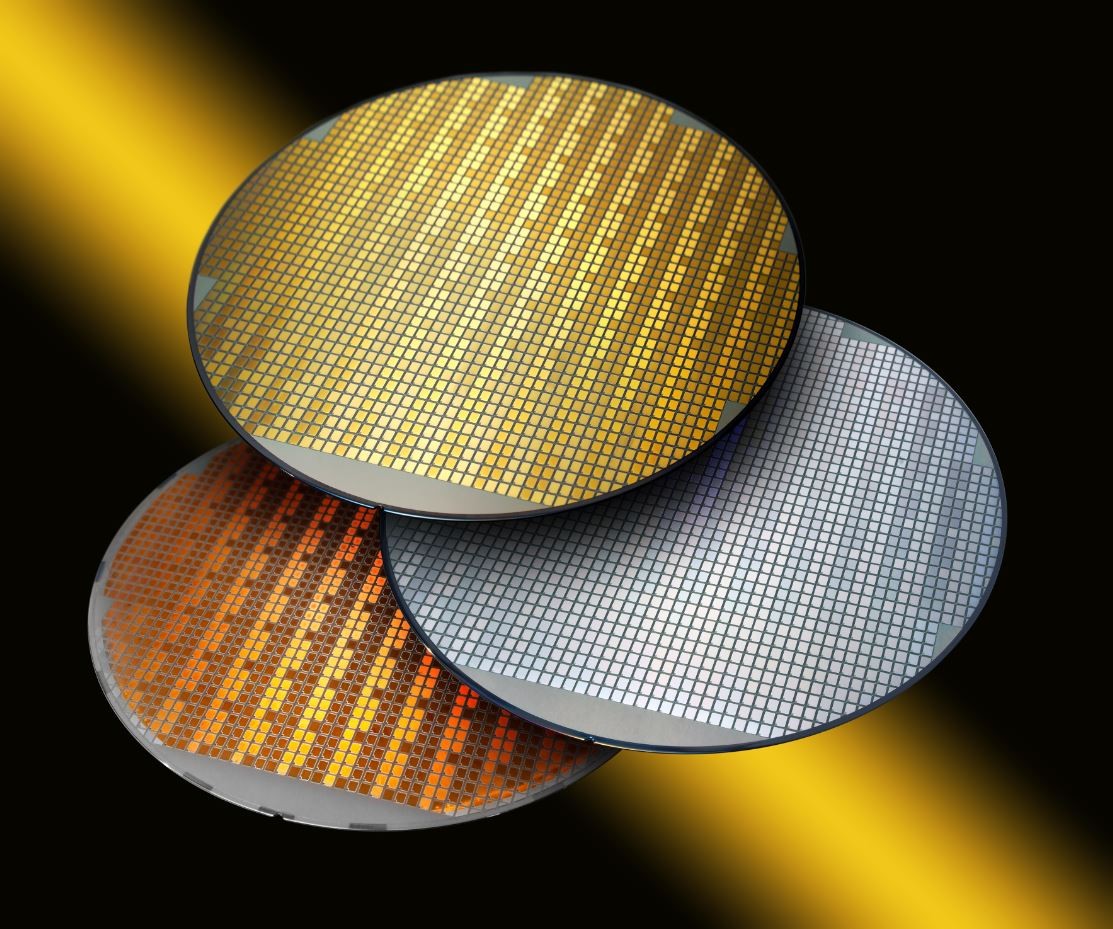

For this reason, the scientists are replacing the conventional production process with highly flexible and fully automated manufacturing. This eliminates some energy-intensive manufacturing steps such as soldering oven processes. Accordingly, less energy is required and the production chain is shortened. One focus of FlaMe is the use of new technologies in the manufacturing process. These include, in particular, laser-based wire bonding, plasma spraying and 3D printing technology. These make it possible to control and target the energy input. This is made possible by adapted power electronics, which are adapted to the requirements of the new manufacturing processes. In addition, GaN components are being developed which, apart from their expected increase in efficiency in the end applications, are directly compatible with the new manufacturing processes.

Sustainable, economical use of materials

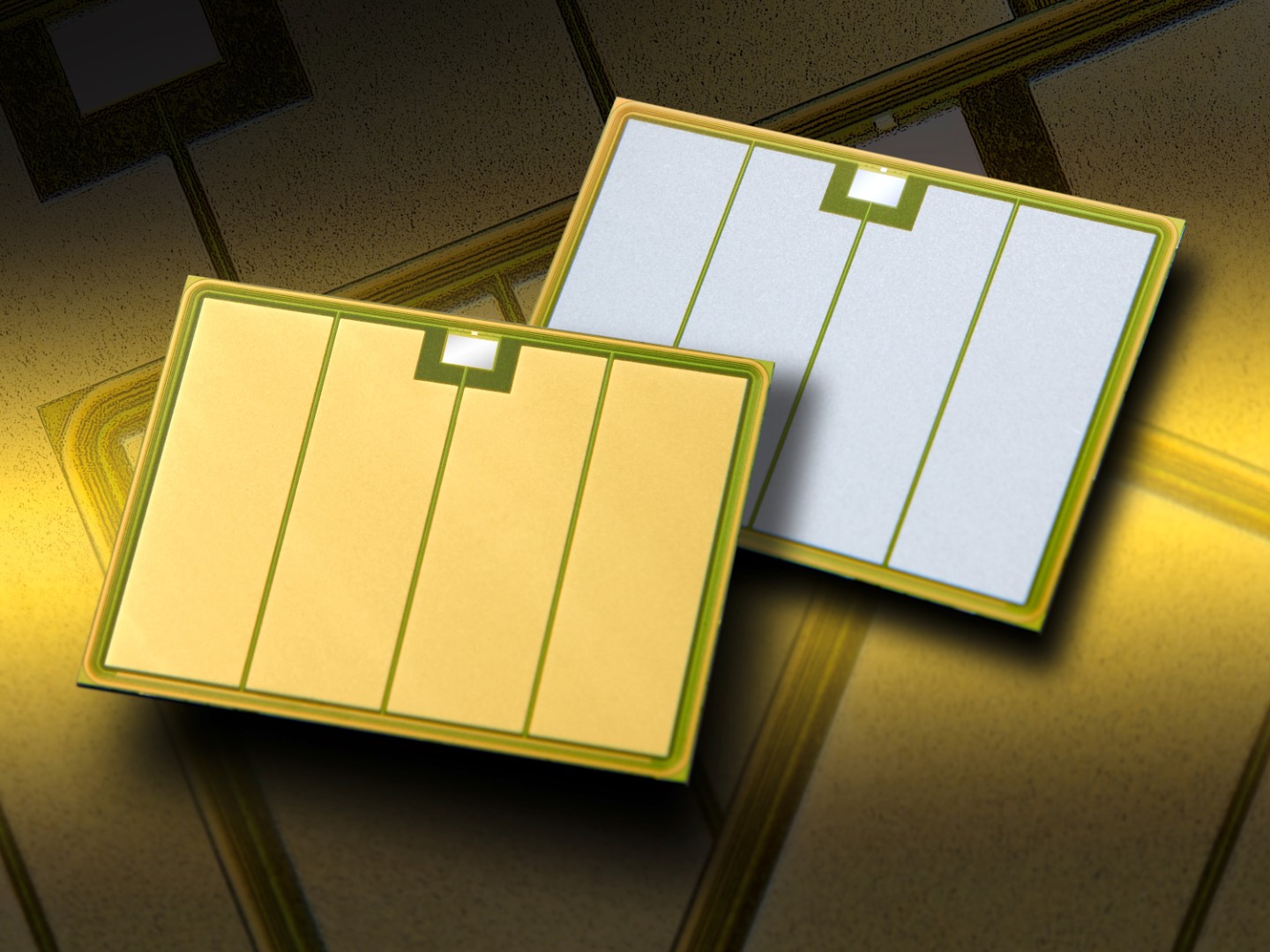

FlaMe should not only make the production process more flexible and energy efficient, but also help to use and save materials in a sustainable way. Some components of a power module are made of aluminum. The project partners now want to replace this with copper. Copper ensures significantly higher power density and a longer service life for the power module. Both aspects mean that the total number of modules required is reduced. This reduces energy consumption both in raw material extraction, production and in the application. In addition, the pure copper compounds make it easier to recover the material. The FlaMe research project thus makes an important contribution to the sustainable production and use of power modules.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology