SiLiNE

Si anodes: The next step in battery technology

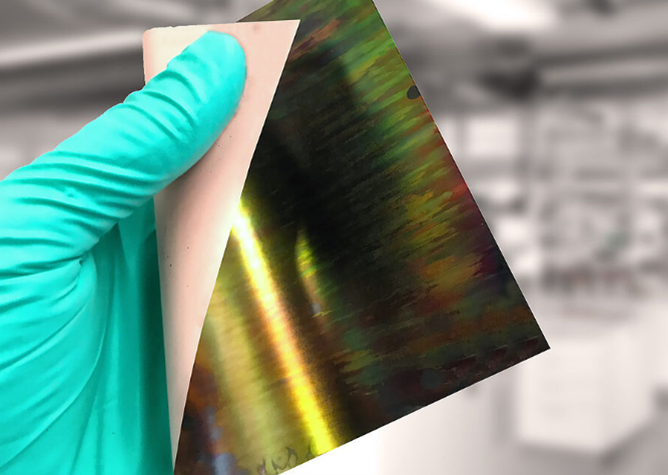

In previous projects, researchers developed Si anodes with a capacity of up to 3150 mAh/g, which are now to be integrated into high-performance pouch cells with an energy density of up to 1000 Wh/l. Pouch cells consist of several superimposed layers of positive and negative electrodes, separated by thin separators - similar to the pages of a stack of paper. This flat and flexible cell format enables efficient use of the available space and improves the integration of silicon film anodes.

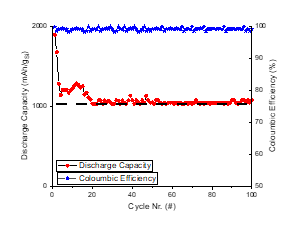

The use of porous silicon anodes contributes to improved performance over longer periods of time and by using pure silicon anodes, the capacity of lithium-ion batteries can be increased tenfold compared to conventional graphite anodes. The consistent Coulomb efficiency of almost 100 % indicates high energy efficiency and low energy losses. In addition to this increase in performance, the focus is on developing a manufacturing technology that is suitable for large-scale production. Optimized manufacturing processes are the key to successfully integrating silicon anodes into industrial cell production and thus driving forward the next generation of high-performance lithium-ion batteries.

Cooperation for progress

This is achieved through the cooperation of several partners who contribute their respective expertise. RENA Technologies uses its know-how in mechanical engineering and process development to make the technology scalable. The Christian-Albrechts-Universität zu Kiel provides valuable knowledge from materials science to optimize the anode materials. We at Fraunhofer ISIT complement the team with our experience in the development of pouch cells and support the optimization of the manufacturing processes to ensure clean and damage-free anodes.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology