Press Release

Fraunhofer institutes help small and medium-sized businesses develop innovative ultrasonic sensors

Many monitoring, sensing and characterization tasks in industry today are based on classic ultrasonic sensors. Micromachined ultrasonic transducers (MUTs) represent an innovative and effective development that can open up new applications thanks to their compact design and efficiency. However, the investment costs for the development of such MUTs are too high for many small and medium-sized enterprises (SMEs). Three Fraunhofer institutes are therefore jointly developing an application platform that will also enable SMEs to use MUTs. The institutes will develop various micromachined devices and pilot products together with industrial partners.

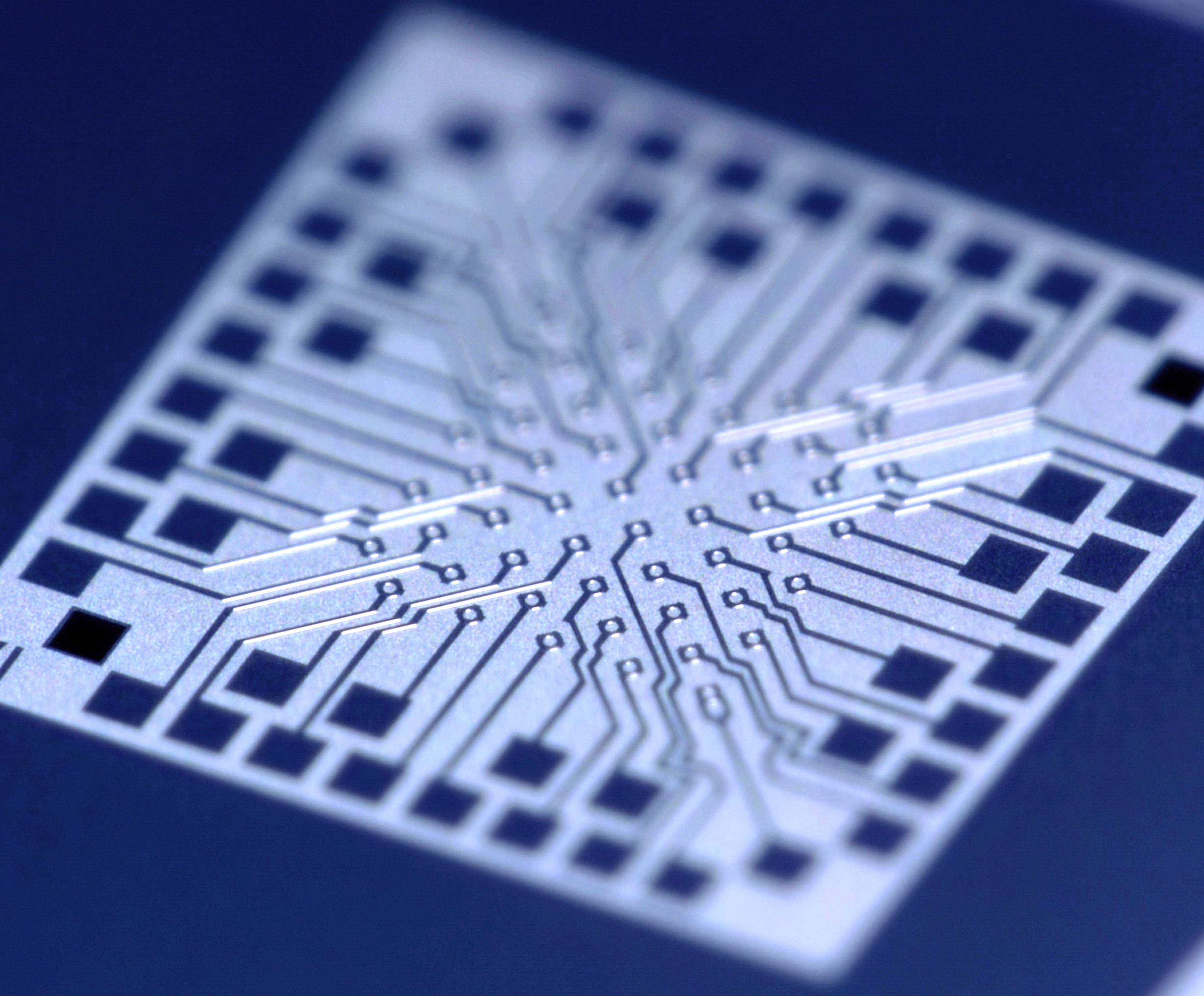

Whether distance measurement and micropositioning, gesture control and collision sensing, endoscopy and sonography – ultrasonic sensors have formed the basis of industry, medicine and mobility for years. Currently, these application-specific sensors are mostly developed and manufactured by SMEs themselves. The use of modern micromachined ultrasonic transducers allows highly compact systems, increased sensitivity as well as an efficient use of array functionalities such as imaging or directivity. In addition, materials that are harmful to health and the environment can be avoided. However, this is offset by the additional, usually high, costs of developing these semiconductor-based MUTs, which are often hard to bear for many small and medium-sized companies. An alliance of three Fraunhofer Institutes aims to remedy this situation.

“Together with the Fraunhofer Institute for Silicon Technology ISIT and the Fraunhofer Institute for Electronic Nano Systems ENAS we want to build an MUT platform. Using a modular approach, we can use it to quickly and efficiently adapt and develop innovative ultrasound systems to specific applications,” explains Jörg Amelung from the Fraunhofer Institute for Photonic Microsystems IPMS. Funded by the Fraunhofer-Gesellschaft, the project is aimed specifically at small and medium-sized enterprises. “By bundling our competencies, we are creating an effective alliance that not only ensures a broad range of applications through its technology portfolio, but also has the infrastructure for pilot production in its own clean rooms,” says Amelung. “This closes the gap between academic research and industrial development and offers SMEs an attractive overall package.”

As part of the development of the MUT platform, three central SME research fields, production technology, human-machine interaction and medical technology, will be addressed. “We believe that the key features of MUTS, miniaturization, improved sensitivity of ultrasonic elements and array functionality, create significant added value here,” explains Dr. Fabian Lofink, head of the business unit “MEMS Applications” at Fraunhofer ISIT.

Attractive offering along the entire value chain from a single source

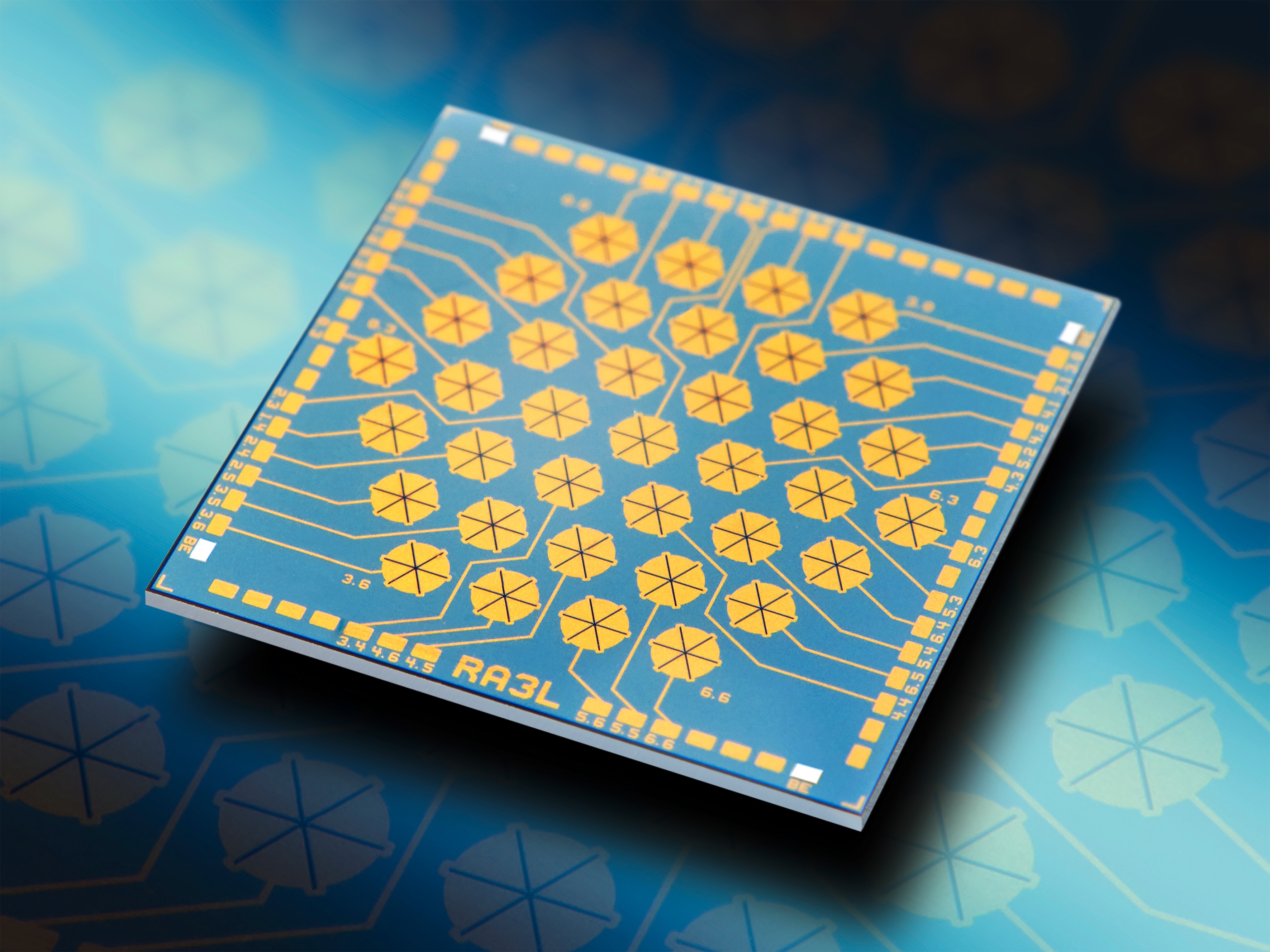

The three Fraunhofer institutes ISIT, ENAS and IPMS have been the leading competence base for micromechanical ultrasonic devices and systems within the Research Fab Mikroelectronics Germany (FMD) for years. Fraunhofer IPMS focuses on capacitive (CMUT) and electrostatic (NED) solutions, while Fraunhofer ISIT concentrates on piezoelectric (PMUT) ultrasonic transducers. Fraunhofer ENAS is working on the development of both capacitive (CMUT) and piezoelectric (PMUT) ultrasonic transducers. Due to the different technologies of the institutes, solutions can be offered for a wide range of applications in the entire frequency range from 20 kHz to 20 MHz. From design, manufacturing, characterization, assembly and interconnection technology to system integration, the institutes can jointly offer application-specific development services along the entire value chain.

Fraunhofer Institute for Silicon Technology

Fraunhofer Institute for Silicon Technology